Prefab under control, from floor to console

Prefab concrete elements are popular, from beams and columns to floor and wall elements. And with good reason. They speed up construction and improve quality, but also present new challenges for the constructor. Prefab concrete elements must comply with the standard rules for stability and strength, both in use and during transport and assembly. Each part of the prefab construction has its own specific points of attention.

The power starts in the floor

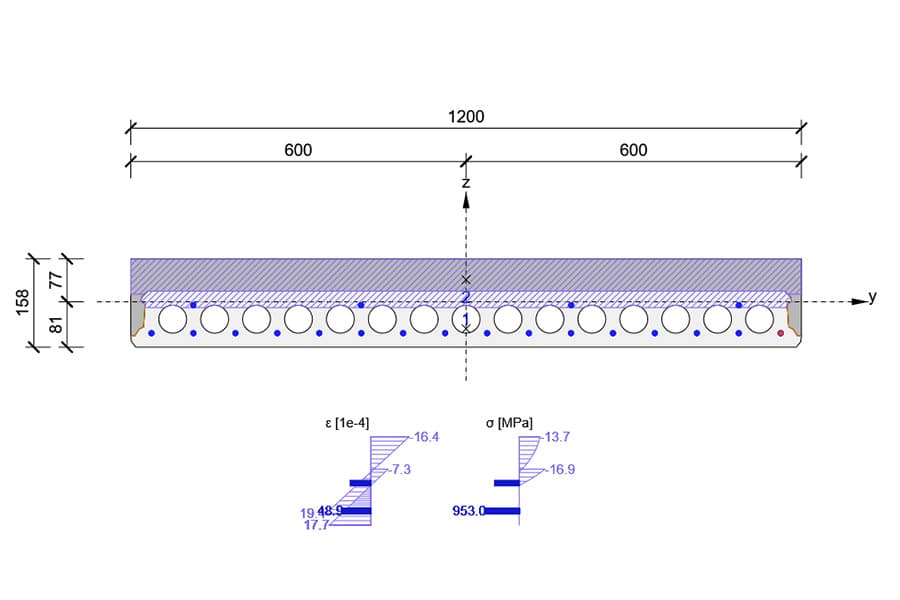

More than 80% of all floors are constructed using prefabricated concrete, with hollow core slabs being the most standardized. IDEA StatiCa Beam and RCS make it possible to easily model and analyze such cross-sections, including any screed layer and shear verification in the connection surface. The various construction phases from production to end of life can be checked, including prestressing and the long-term effects of creep and shrinkage.

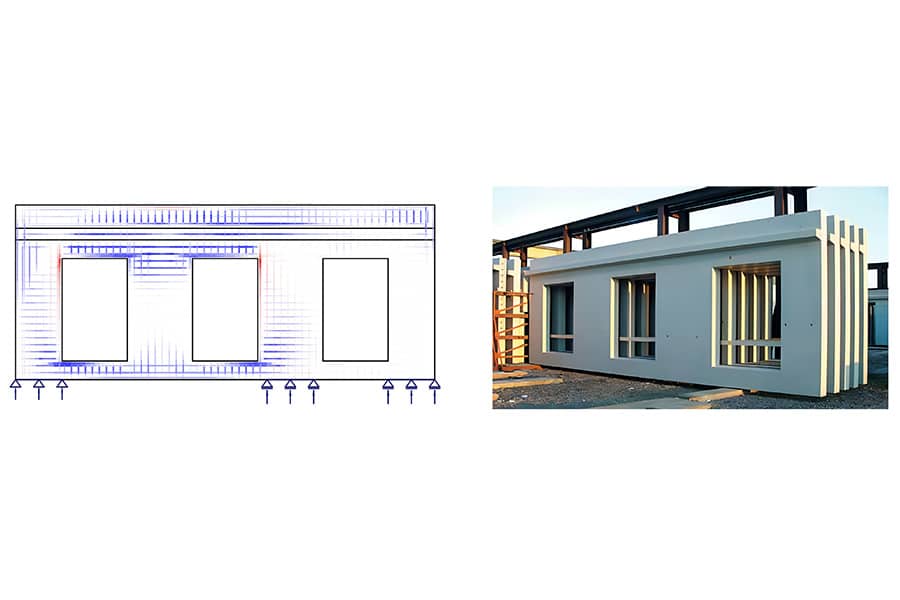

The forces from the hollow core slabs are usually transferred via a wall or beam. A typical example is a load-bearing inner cavity wall with window openings and a support lug for the floor slabs. The reinforcement around the openings is a critical point of attention here. Especially when the concrete element has to function as a wall beam, a non-linear FEM analysis is necessary. With IDEA StatiCa Detail, wall beams can be accurately designed and calculated, including reinforcement and crack width control.

Who goes first?

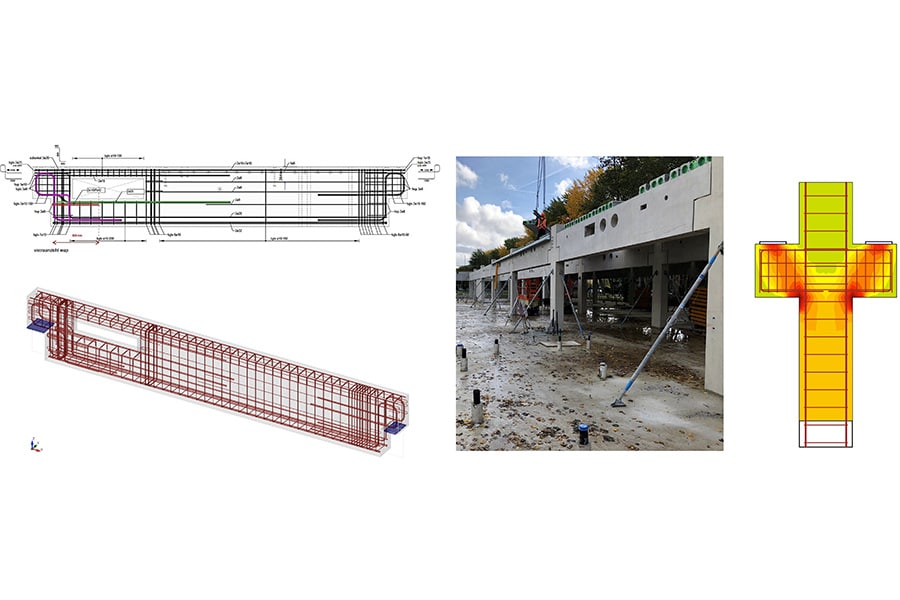

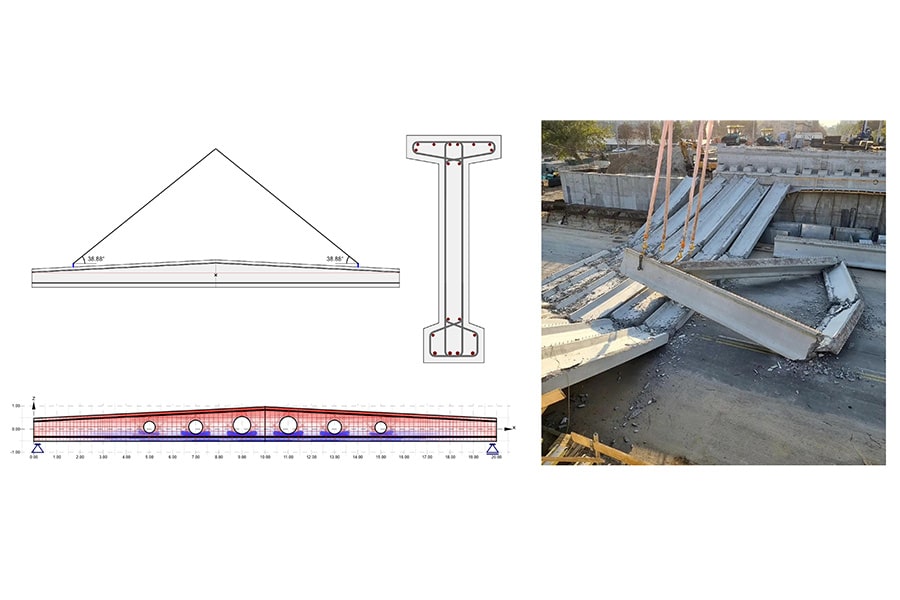

Prefab beams are efficient, until you need to save space. Then large openings for installations appear and, as a structural engineer, you end up in a D-area where the classic Bernoulli hypothesis no longer works. Easily model a prefab beam with tooth supports and openings in the IDEA StatiCa Detail application. The program calculates the stress fields and shows where cracks occur, allowing you to adjust the reinforcement accordingly.

The force from the beam passes through the opening, via the console, into the column. A good reinforcement design is essential to limit cracking in the support. The console supports the beam, the reinforcement supports the console, and you support the responsibility.

Lifting without headaches

Structural elements must not only perform adequately during the service phase, but also during construction in situations such as transport and lifting on the construction site. The ancient Egyptians were already aware of this. This is crucial for prefabricated construction, because the elements are produced in the factory and then transported and assembled as a whole.

By combining prestressing and prefabrication, larger spans can be achieved with slimmer cross-sections. However, this requires extra effort from the structural engineer, because slender beams are susceptible to instability during their journey to their final destination. What is stable in its final state can suddenly become vulnerable to lateral torsional buckling during transport. IDEA StatiCa Beam provides greater certainty in this regard. The time-dependent analysis (TDA) takes into account creep, shrinkage, and aging of the concrete. In addition, you can check the stability during the lifting phase or during transport.

A well-stocked toolbox

Prefabrication is an efficient way of building, but it requires careful engineering. IDEA StatiCa offers a complete toolbox for this purpose. From simple cross-sections to complex D-areas: every prefabricated element can be reliably calculated. Thanks to modules such as RCS, Beam, Detail, and Member, the structural engineer has all the tools needed to comprehensively assess the behavior of prefabricated components. In addition, the software generates reports and parts lists that can be used immediately for checking, documentation, or production. This speeds up the workflow and increases the reliability of the entire design process.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met IDEA StatiCa BeNeLux B.V..

Contact opnemen

Contact opnemen