The block box of LEAN

Building block by block for a more efficient and future-proof steel construction industry

No two steel structures are the same. Unique designs, tight deadlines and complex production processes make efficiency a prerequisite for success. At the same time, companies struggle with real-life questions such as, “How do I bring peace of mind to my employees? How do I create space to work? How do I shorten my lead time? How do I grow without losing the character of our family business? And how do I professionalize and teach my team to look at things differently?”

This is where LEAN comes in: as a practical tool to organize smarter together. Forget the call from above to push harder or work faster. LEAN is about designing processes in such a way that teams can do more with less effort, gain an overview and experience peace. Rest that ultimately leads to operational growth.

But how do you start this in steel construction? How do you concretize what LEAN can mean for your manufacturing company, with its specific challenges and dynamics? During a knowledge session held by Liemar Software, in cooperation with network organization Infosteel and Indus, company executives, project managers and production managers from the steel construction sector had the opportunity to experience this personally on September 11.

“Liemar organizes these sessions for the benefit of the entire industry,” says Niels Oudenaarden, Commercial Director at Liemar. “By sharing knowledge and insights on collaboration, process design and continuous improvement, steel construction companies can inspire each other, strengthen each other and achieve higher performance together. Knowledge sharing is the engine of progress.”

Experiencing LEAN

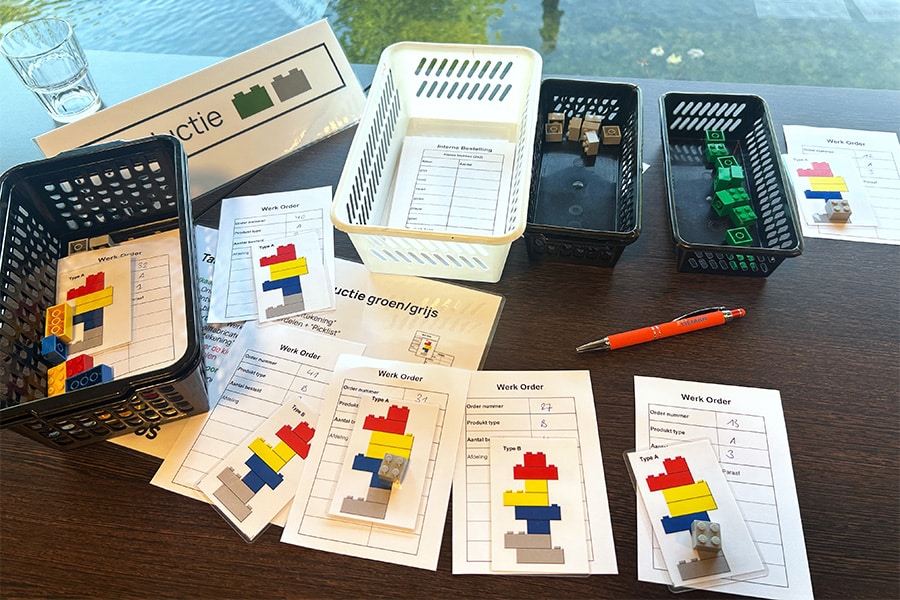

How about we literally build block by block to experience LEAN? Under Indus' guidance, the group got to work with LEGO creations, based on an assignment card. Without first taking a step back, they began to build blindly, just as they often do on the shop floor. That made one thing clear: stepping back and thinking critically in advance is essential, even in daily practice.

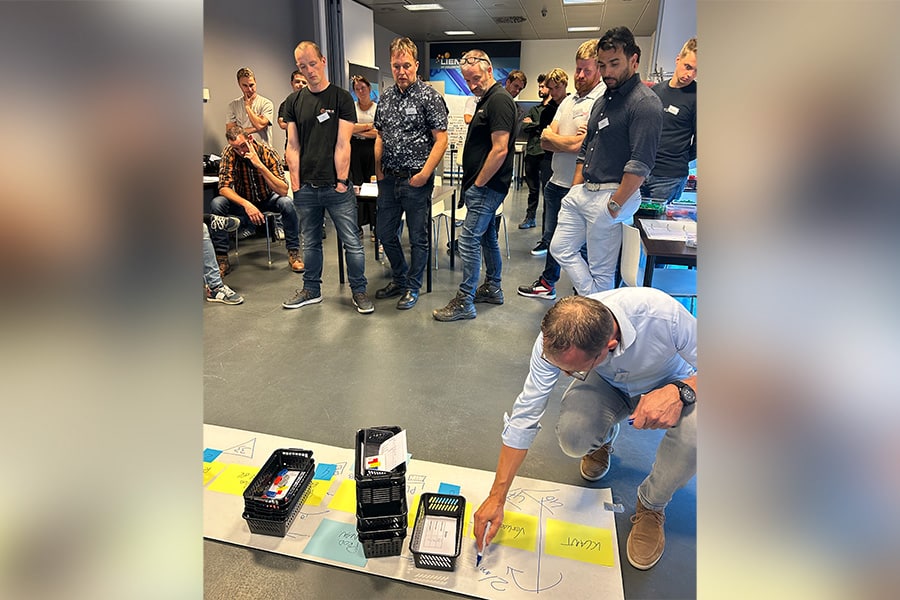

Visualizing and measuring resources, outputs and flows quickly revealed bottlenecks. A ‘safety ribbon’ depicted the entire flow and made visible how processes intersected unnecessarily, which parts were too far apart, and where movements were wasteful. Participants were challenged to think about how small adjustments in sequence, placement or collaboration could significantly improve flow and output.

Block by block it became apparent that LEAN is much more than a theoretical method. It is a valuable philosophy with which you optimize processes, increase the performance of departments and learn to look beyond departments and organize. The building exercise showed how important it is to set common goals, make the flow transparent and define KPIs. Because only what you measure, you can improve and in this way LEAN becomes tangible and applicable on your own shop floor.

LEAN in practice

Under the umbrella term ‘knowledge sharing as a motor,’ participants were also offered a factory visit and inspiration from practice. Modulyss, manufacturer of carpet tiles in Sint-Niklaas, showed how LEAN runs through the entire production chain: from the design of the production itself to conscious choices about material use and energy consumption. By bringing machines together and enabling centralized control by an operator, walking distances and movements are significantly reduced and changeover times shortened. Seemingly small adjustments, such as smarter use of yarn, cardboard and coating, have a major impact on efficiency, energy and material consumption.

For Vytech Industrial Solutions, LEAN starts with thoughtful analysis with intentional and planned maintenance as a critical component. Start scheduling maintenance moments in a targeted way instead of waiting for downtimes. Rearrange machines for maximum performance, taking into account capacity, ergonomics, safety, lack of space and efficiency. Tools like SMART Scheduling help reduce forklift movements, allowing for safer operations and reduced tire wear.

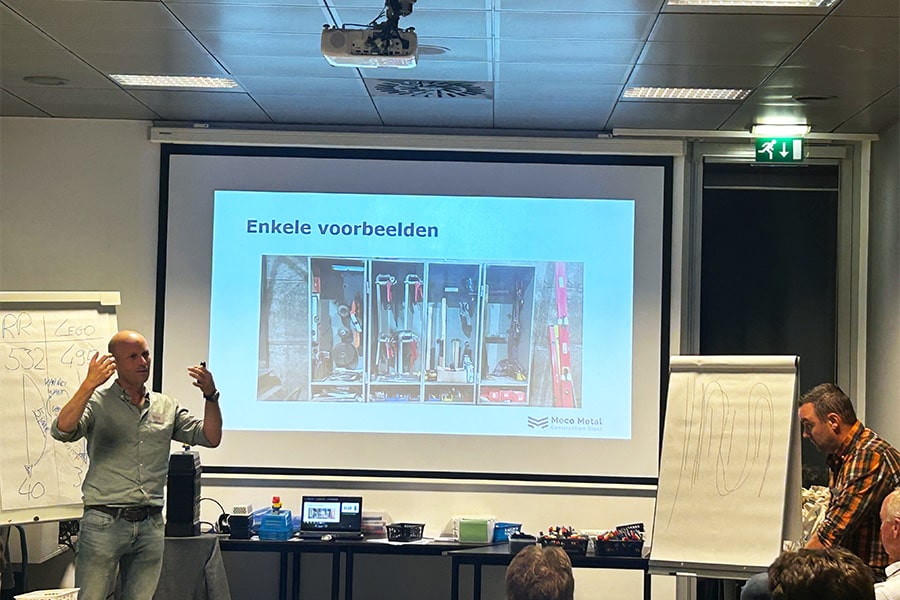

At Meco Metal, part of the Altez Group, it is all about integrating LEAN into daily operations and creating support among employees. By actively involving operators and implementing improvements together, a shared way of looking and thinking is created, as a result of which the benefits of LEAN are widely supported and anchored in the organization.

All the cubes fall together

Slowly but surely, all the pieces fell together throughout the evening. The LEGO workshop made visible how patterns, small changes and well-considered choices have their impact on the flow. At the same time it became tangible how LEAN takes knowledge out of the head of one employee and captures it in systems, software and shared practices, so that insights are not lost but become accessible to everyone. There was also cordial cooperation and coordination and a nice interaction between the manufacturing companies present.

Knowledge sharing as an engine for the sector, brings us back to the raison d'être of these Liemar sessions: building block by block on a more efficient and future-proof steel construction sector. Participants reported driving home with an enlightening, educational summit feeling, ready to get to work block by block themselves.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Liemar Software BV.

Contact opnemen

Contact opnemen