Through smart automation, humans and machines always get the right information, data and resources at the right time

The son of a contractor, Henk Jan Nieuwenhuis grew up in the world of manufacturing construction companies, where prefabricated construction made its early appearance. In 1998 he graduated in the use of 3D models and digital processes within construction. For the past ten years, he has focused entirely on optimizing flow in precast manufacturing companies. His vision: through smart automation, man and machine always get the right information, data and resources at the right time.

A critical component in Nieuwenhuis' approach is the adoption of an open architecture. This makes it possible to cleverly integrate existing software into one coherent solution. He also strongly believes in a product-oriented approach to digital transformation in the (prefab) construction industry. "At production sites, different elements for different projects are produced simultaneously," he explains. "To keep an overview, it is essential to split these projects into individual parts in an automated way. And that down to the level of the element and any sub-elements. This may sound futuristic, but with today's technology it is today's reality. To choose this is to choose a digital transition of your manufacturing business."

3D model as a central source

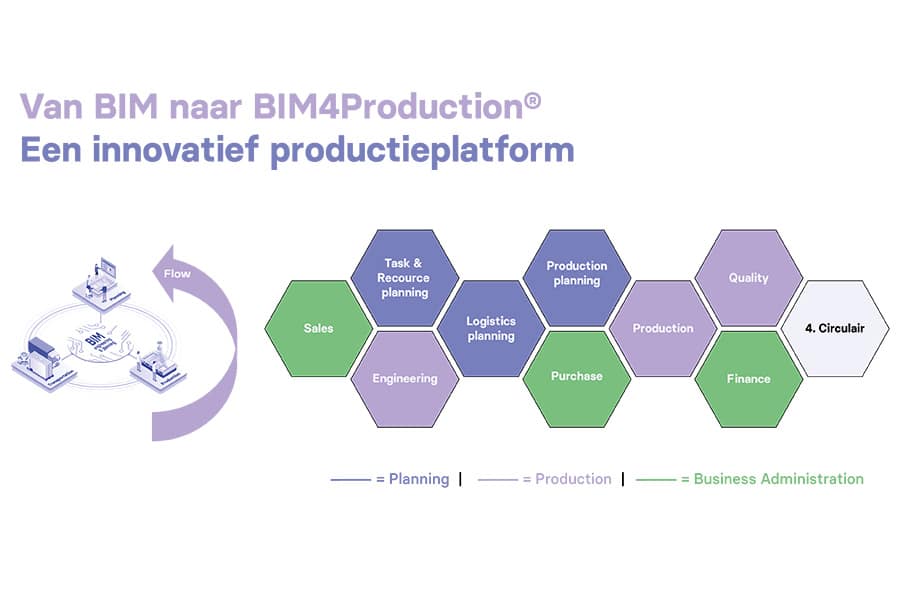

"An efficient flow in your production occurs when the 'What,' 'When,' and 'How' are optimally aligned," states Nieuwenhuis. "That starts with a clear understanding of 'What' needs to be produced. This is why within BIM4Production® we prefer to always work from a 3D model as the central source. This model forms the basis for the entire production process, from procurement to delivery." BIM4Production® automatically distills the individual elements from the 3D drawing, allowing all parties, departments and employees involved to work with the same reliable data. This ensures a smooth flow of information and prevents errors and delays in production.

Smart planning and production

With an optimized "What" comes a focus on the "When" and "How," or planning and production. "There is already a lot of good software available," observes Nieuwenhuis. "The challenge lies in the integration and accessibility of information from all these systems. By bringing everything together in one overview, you get a full grip on the process and you can switch quickly. This makes it possible to identify bottlenecks early and resolve them before they disrupt production." He says the strength of BIM4Production® lies in leveraging existing software and systems that companies are already using. This avoids high development costs and speeds up the implementation of digital working methods.

Collaborating across borders

One of the most important lessons Nieuwenhuis learned in recent years is that an integrated platform is necessary for collaboration in the construction industry. "Whether you're in wood frame, facade, aluminum or concrete construction, a shared digital language is essential," he says. "BIM4Production® was developed with that in mind: we link as many existing software solutions as possible to our platform. Where gaps arise, we develop new modules. This is how we ensure that the platform connects to the entire precast construction sector."

BIM4Production® is a Software-as-a-Service (SaaS) solution. This means that new features and functions become available to all (existing) customers. A production company thus remains continuously up-to-date via the platform. This gives companies a strategic advantage in an increasingly digitizing sector.

Link

Nieuwenhuis looks confidently to the future. "Many manufacturing companies have already smartly digitized their business administration and have planning tools in place. The next step is to link these systems to an integrated digital workflow based on the 'What,' 'How,' and 'When.' This ensures that both man and machine always have the right information and resources at the right time. The key to optimal flow."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met BIM4Production®.

Contact opnemen

Contact opnemen