amsterdam van der valk hotel | A project of extremes

In the far east side of Amsterdam's Zuidas, Van der Valk has "found" a triangular plot that will be fully built on. The hotel chain has contracted Pleijsier Bouw as the main contractor. The shell consists of part cast-in-place concrete and part precast concrete with a visible 'cut' on the seventh floor. A project of extremes with a prestressing method that is innovative by Dutch standards.

The first pile went into the ground at the end of November 2017, project coordinator Mark Moerdijk of Pleijsier Bouw looks back. "We are responsible from the groundwork to the delivery of the thirteen-story shell (55 meters high with eaves). Or rather, 'shell plus,' because the interior walls, screeds, stucco and tile work in the hotel rooms are also within our scope. After the piles were drilled, we were able to start the concrete work in early 2018. The first seven layers of the hotel were poured on site, and the seven layers of the bedhouse (234 rooms) above that were prefabricated."

Transition Floor

Pleijsier Bouw was working on the first seven layers from early 2018 through February 2019, while the precast portion was completed in just four months. "It is totally disproportionate, but inherent in the design," Moerdijk outlines. "The reception and shipping areas are on the first floor. Above that is the parking garage over four levels with some technical spaces here and there. The cores are all cast-in-place and executed as exposed concrete, as are a number of precast columns. The parking garage is completely open and, unlike the first floor, will not have a curtain wall. Above the parking garage are two commercial layers that include a restaurant on the fifth floor and the conference center with meeting rooms on floor six. The floor of the seventh floor forms the so-called transition floor, on which the seven-story bedhouse of prefabricated elements rests. The transition floor is as much as 90 centimeters thick and constructed as a table structure that transfers all the forces of the bedhouse to the underlying cores and columns."

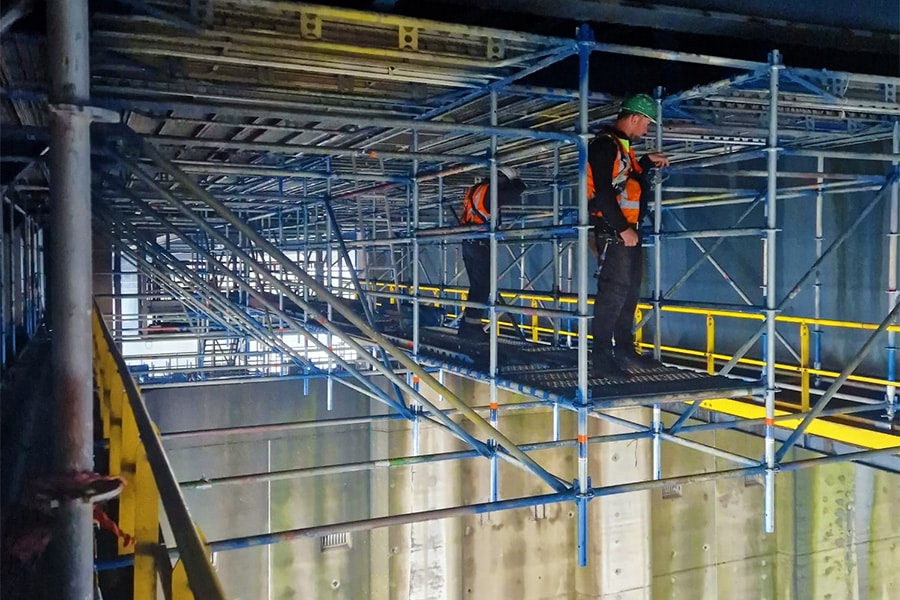

Innovative preload.

Preload

The first seven layers of the new hotel are equipped with an innovative prestressing system. Moerdijk: "Our subcontractor Van Muijen Beton has outsourced the prestressing to Interspan, a party from England with a completely unique methodology. The prestressing strands are not loose in a tube, but are poured with a mortar. Should you pierce a strand, stability is guaranteed. The attached system is fairly innovative and not common in the Netherlands. It also means that much less additional reinforcement needs to be applied by applying the attached strands. The parking layers, for example, are only equipped with prestressing strands and a shrinkage net at the bottom of the floor, so no additional reinforcement. Not very common, of course. Just as spectacular was the tensioning of the floor after pouring. The strands were gradually tensioned the very day after the first pour to reach the full 100% after two weeks, stretching the strands by up to 25 centimeters."

The new hotel was designed fully 3D in BIM, according to Moerdijk. "Besides being technical, it is also aesthetically a far from ordinary object, with its unique design. The official opening will take place in May 2020."