Ham Concrete Plant | Specialist develops automatically controlled turnkey mixing plant with cube lanes to production

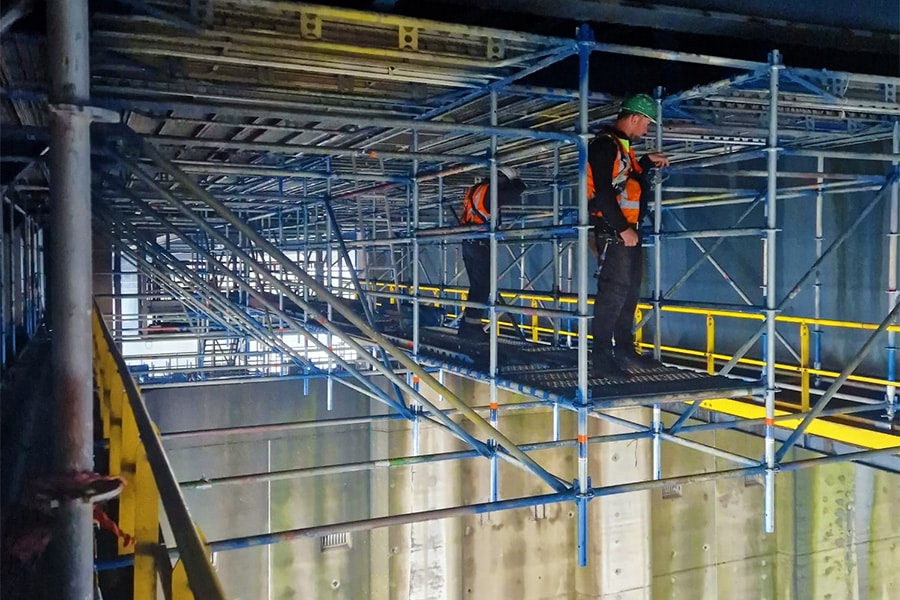

Delden-based Rotonde International BV recently developed and installed the complete mixing plant with automatic control in combination with cube conveyors and half portals with concrete distributors to the production machines in Fingo's new concrete plant.

"The management of the concrete vaulting specialist was very impressed with our solution for an equivalent project in the Netherlands and the installations built in our own production hall in Delden," says director Erik Wilmink. "As with many of our projects, this is also a turnkey solution, which was specially tailored to the customer's desired production capacity. After all, at Fingo they work in three shifts, so the plant keeps running day and night to always provide the operators on the shop floor with concrete of perfect quality." The entire project from commissioning over engineering, design and production to assembly and delivery took about one year. Rotonde International started the preparations in February 2018 and from May 2018 the execution, to be completed completely according to the predetermined schedule in February 2019.

Rotonde does not provide standard solutions, but tailors installations to the specific needs of each project.

Partner in concrete plants

Founded in 1991, Rotonde International specializes in the engineering and construction of concrete mortar plants, mixing plants, filling systems, individual components and partial solutions. "Every project is unique. Therefore, we always start from the specific needs of the customer. We do not provide standard services, but determine which priorities should be set according to the operations," Wilmink states. "Thanks to short lines of communication, clear planning and concrete agreements with the client on the one hand, but also between the designers, preparers and project managers within Rotonde on the other, we are able to adequately and competently approach and execute each project." The company also has an experienced service team for installation, maintenance, overhaul and repair of systems. After all, expert service and structural maintenance of installations significantly reduces the risk of breakdowns, and in the event of any technical problems, clients can also immediately call on the know-how of the specialists. Other reference projects for Rotonde International include the concrete plants of Multi-Mix (Gent/Wondelgem) and Amacro (Beersel) in Belgium and those of Bollenbeton (Hillegom), Dycore (Oosterhout) and LBC (Leeuwarden) in the Netherlands. The specialist also developed the greenest concrete plant in all of the Netherlands, for the Theo Pouw Groep in Utrecht.