Safe hoisting comes at a price

Many Dutch producers of structural concrete elements produce under KOMO certification. Compliance with Criteria 73 is mandatory for many KOMO BRLs. This document also sets requirements for lifting equipment and transport anchors. Recently, these have to comply with NEN-EN 13155:2020. However, many companies forget that when they import a transport anchor with CE marking, they are also legally responsible for the technical safety aspects of this anchor. Lifting safety is the poor relation of the precast concrete industry and deserves more attention.

Basically, European laws and standards guarantee a very high level of safety. In accordance with the Machinery Directive - the European law that all lifting equipment traded within the EU must comply with - the company importing the goods into the European Union is legally responsible, and therefore responsible for all legal requirements that are in place. Even if you import a transport anchor with CE marking on it from China, you are legally responsible for its safety. Having CE put on it is only the last step in a long process. The law does not require any third-party inspection of lifting equipment before it is placed on the market. The Machinery Directive does require, however, that there be a manual, technical file and factory production control (FPC).

Machinery Directive

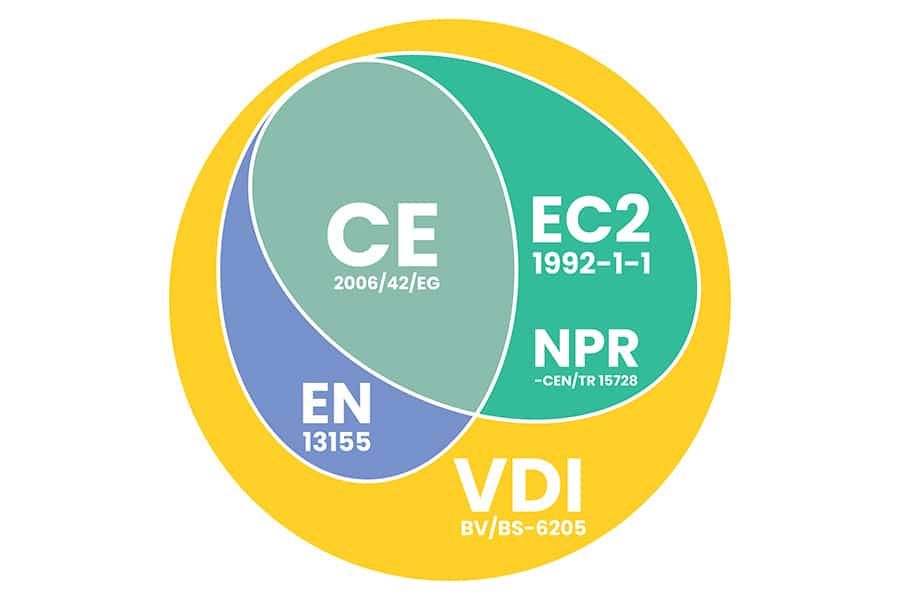

The Machinery Directive is a broad legislative document that gives little specific information about transport anchors for lifting concrete elements. For this reason, more specific guidelines have been written such as the CEN/TR 15728 in 2008 (with the latest version from 2016) and the BV-BS 6205 in 2012 (latest version is from 2021) from the VDI (Verein Deutscher Ingenieure). Whereas the Machinery Directive gives global safety factors for the material used of anchor and lifting key, the VDI Directive and CEN/TR 15728 also address the interaction of the transport anchor with concrete and reinforcement. In addition to the Machinery Directive, harmonized European standards also exist. These are non-binding technical specifications that go much deeper into a particular product or category of products. NEN-EN 13155 was already the standard for lifting equipment, such as pallet hooks and equalizers, but the new 2020 version has been expanded to include transport anchor systems for use in precast concrete. The new version incorporates knowledge from CEN/TR 15728 and VDI guideline BV-BS 6205. The result is a higher level of safety that precast concrete producers can apply to transport anchors.

Criteria 73

Many Dutch producers of structural concrete elements produce under KOMO certification. The production of concrete elements according to the KOMO Assessment Guidelines (BRL) is the practical standard in the Netherlands and increases quality. Many of these BRLs refer to Criteria 73 for the quality system. This document gives requirements for the quality system in the concrete factory. Compliance with Criteria 73 is mandatory for many KOMO BRLs. The latest Criteria 73 amendment from November 2024 requires transport anchors to comply with NEN-EN 13155:2020. It is intended to ensure a higher level of safety for lifting concrete elements under KOMO certification.

EC declaration of conformity

To see whether a product complies with NEN-EN 13155:2020, the EC Declaration of Conformity (DoC) can be consulted. With this document the manufacturer or importer declares that the product complies with the Machinery Directive and any applied standards and directives. All lifting equipment that is traded within the EU and for which a European directive exists, is required to have a CE mark. This also obligates the manufacturer or importer to prepare the EC Declaration of Conformity for the product in question and make it available to the market.

Opaque playing field

Lifting safety is the poor relation of the precast concrete industry. The cost of transport anchors is only a fraction of the total cost of a concrete element, and the consequences of failure are potentially disastrous. No one wants a (near) accident on their conscience, but the opaque playing field makes it difficult to discern when safety comes at the expense of price. "Purchasers and quality managers of concrete plants would do well to actively ask their suppliers for the required documents, such as the EC Declaration of Conformity (DoC) and the manual," advises Richard van der Ham, Technical Commercial Director Netherlands at the Terwa Group.

This article was co-authored with Joris Damoiseaux and Cas Borghouts.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met TERWA.

Contact opnemen

Contact opnemen