Carrying CO2 to the sea

Compressor station of Porthos central link in CO2-storage under the North Sea

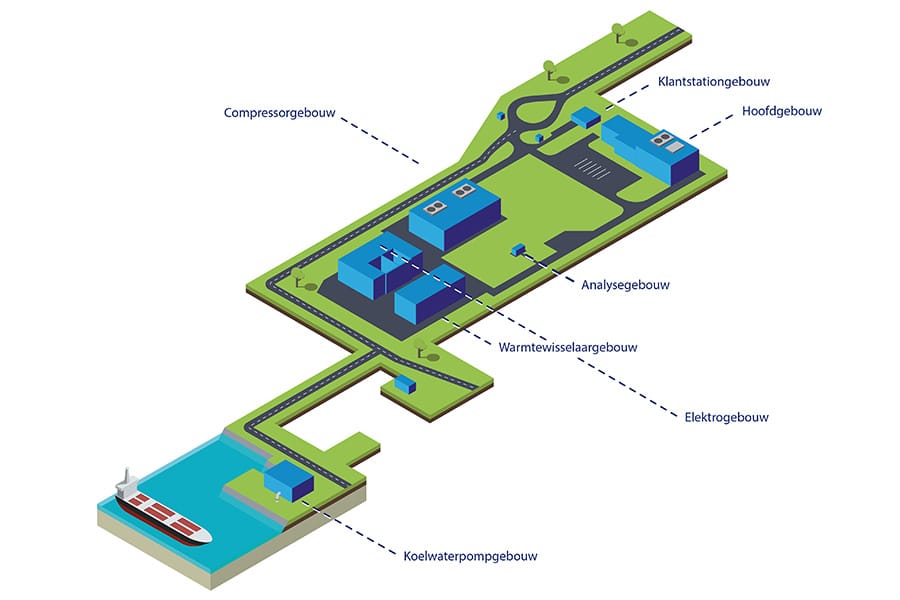

Starting in 2026, CO2 from a number of industrial companies in the Port of Rotterdam, transported and stored in old gas fields under the North Sea. To realize the complex transport infrastructure, several initiatives have been set up, some of which are working together. One is Porthos, a joint venture of Gasunie, the Port of Rotterdam Authority and EBN with a long land pipeline, a compressor station and a pipeline at sea where CO2 is pumped into a depleted gas field. Almost at the end of the Second Maasvlakte is the heart of the project: the compressor station that collects the CO2 at high pressure and the right temperature.

Porthos is in addition to Aramis and CO2Next one of the collaborations that capture and underground storage of CO2 aim. This Carbon Capture and Storage (CCS) should go a long way in reducing CO2-emissions, especially those from industry. After the State Council gave the green light for the start of Porthos in August 2023, construction of the land pipeline began not long after. This runs from Vondelingenplaat along an extremely laborious 30-km route through the port area, mainly underground, even passing a canal or sea wall up to 50 m deep. From the compressor station, a 22 km pipeline is currently being laid to a drilling platform that will transport CO2-injection wells at depths of 3 to 4 km will pump.

Compressor station

The compressor station's 2-hectare site is sandwiched between the ECT Euromax container terminal and the Maasvlakte Oil Terminal. "This is where the CO2 supplied via a 42-inch pipeline at 30 bar," begins Reinier Lissenberg, construction manager compressor station for Porthos. "At the compressor station site, the gas is filtered and brought to a pressure of 180 bar. This is done through three compressors, one of which acts as a reserve. The building is already prepared for another three compressors for Aramis."

Heat exchanger

Compression releases heat, and to prevent excessive temperatures, the compressors are cooled. "To control the temperature, the compressors are connected to a closed cooling system. In a separate heat exchanger building, this closed system is cooled with water extracted from the Yangtze Canal by a cooling water pump building. Residual heat released from the heat exchanger will find its way to the GATE Terminal, located a little further away, where LNG is converted from liquid to gas. Next to the heat exchanger building is the "electrical building" with the transformers. Here, transformers convert 66 kV to 11 kV and 440 V to power all installations."

Underwater concrete

The construction of the compressor station was awarded to coordinating contractor Bonatti through a European tender, with G. van der Ven BV Aannemingsbedrijf being the coordinating and realizing contractor for the cooling water pump building. Lissenberg: "The deepest point is the basement of the cooling water intake at the Yangtzehaven. Here, in addition to extending a section of quay wall, a construction pit was made with sheet pile walls. Then, at a depth of 9 m, a foundation slab was poured with underwater concrete on which the concrete basement walls were made in a dry pit. The superstructure of the cooling water pump building is precast concrete."

Stabilization Mattress

The highest point will be the compressor building that reaches 13 meters. "This is also the only building that stands on piles; all other buildings are founded on steel," Lissenberg continued. "The compressors and interstage coolers with all the related equipment form a heavy package, generating various loads. Both static and dynamic. Of the 806 CFA piles (piles drilled into the ground with an auger; ed.), one section carries a stabilization mattress, constructed of geotextile and granulate, on which the compressors stand. This mattress handles much of the dynamic loads. The superstructure of the compressor station, like the heat exchange building, is constructed of a steel structure and sandwich panels in a blue color. For the other buildings, the superstructure is made with precast concrete elements. The electrical building received a ceramic facade finish with Mosa tiles in a beautiful sand color. In this way, all the buildings will soon blend into the dune landscape."