Manhattan Urban Residence Roermond

At the head of the Maashaven in Roermond, the exclusive Manhattan Urban Residence was recently completed. The apartment complex is a true eye-catcher in the skyline of Roermond. The century-old family business Timmerfabriek Palmen from Stramproy made the molds for the high-profile design.

Text | Roel van Gils Image | Carpentry Palms

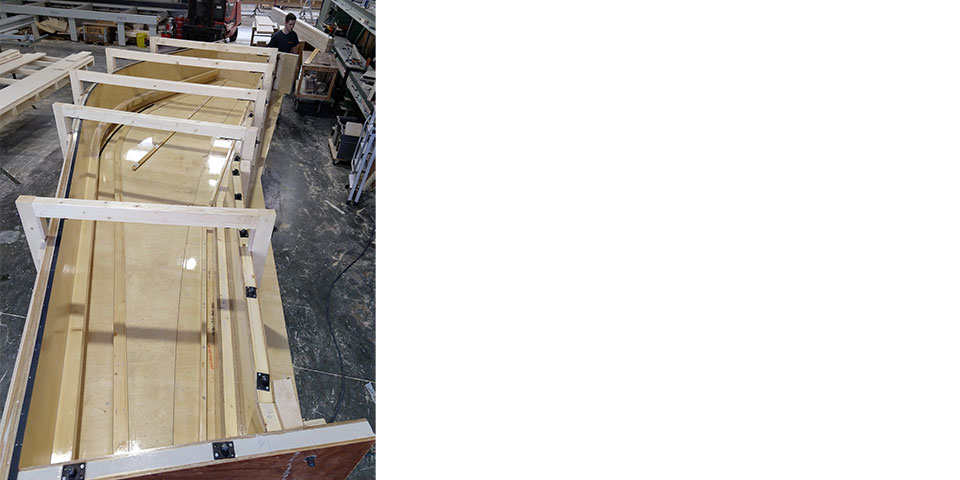

Like a rising spiral, Manhattan Urban Residence towers above the city. Spaciousness, flexibility and beautiful and sustainable materials merge here into a design with a nautical look, befitting its unique location on the Meuse River. Commissioned by Granito Betonindustrie, Timmerfabriek Palmen was responsible for the realization of the molds for the face-defining balcony slabs. "For 200 years we have been engaged in woodworking," says Nol Palmen. "With our machined carpentry workshop, we specialize in the production of stairs and frames for new construction, restoration and renovation applications, while our mold department produces wooden molds for the precast concrete industry."

Curved or double curved, Timmerfabriek Palmen can make any shape you want.

Smooth transitions

"Over the past thirty years, we have built a solid reputation as a supplier of wooden molds for the precast concrete industry," Palmen continued. "These molds are supplied for projects in the Netherlands, Belgium and Germany. Our knowledge and experience is highly valued by our clients, who often contact us as early as the design phase of the project. In this way, we can think along with the project from the beginning and advise the client to come up with the best solution together. This was also the case for Manhattan in Roermond, for which we made the molds for the balcony slabs. In particular, the flowing transitions between the various elements were a point of attention, but we managed to tackle them correctly. We often make molds for similar projects in utility construction, such as the TD-building in Eindhoven or the Sparta Luce complex in Apeldoorn. Furthermore, we also make molds for infrastructure, sports stadiums and works of art."

Latest techniques

"Curved, double-curved, it's all the same to us: we can make any shape in our workshop," says Palmen. "For this we base ourselves on 3D drawings and use the most modern CNC techniques. Each mold is a project in itself on which one or more employees, depending on the size of the mold, work. If desired, we clarify the construction of the mold with a construction sketch. We also supply a fitting list so that our customers' employees know how to convert the mold. We supply molds that more than meet the CUR100 clean concrete standard. Upon request, we incorporate various types of anti-slip or textured surfaces into our molds or numbers, letters and logos can be made in or on the concrete surface. We transport most molds ourselves with our own transport to the customer."

Each mold is a project in itself that one or more employees, depending on the size of the mold, work on.

The molds for Manhattan Urban Residence were delivered neatly on time and on schedule, according to Palmen. "The great thing is that the project is also in our neighborhood, so we can regularly admire the result," he concludes.