Largest onshore wind farm stands near Zeewolde

In Southern Flevoland, the largest wind farm on land in the Netherlands is being built. In an area of 300 square kilometers between Zeewolde and Almere, 220 scattered old turbines will be replaced by 91 large turbines in line arrangements. Starting in 2022, this Windpark Zeewolde must produce two and a half times as much power as the old turbines, which must all be demolished by 2025. What is special is that the developer of 83 of the 91 turbines - Windpark Zeewolde BV - is owned by more than two hundred farmers, residents and landowners from Zeewolde. This makes Windpark Zeewolde the largest community project in Europe.

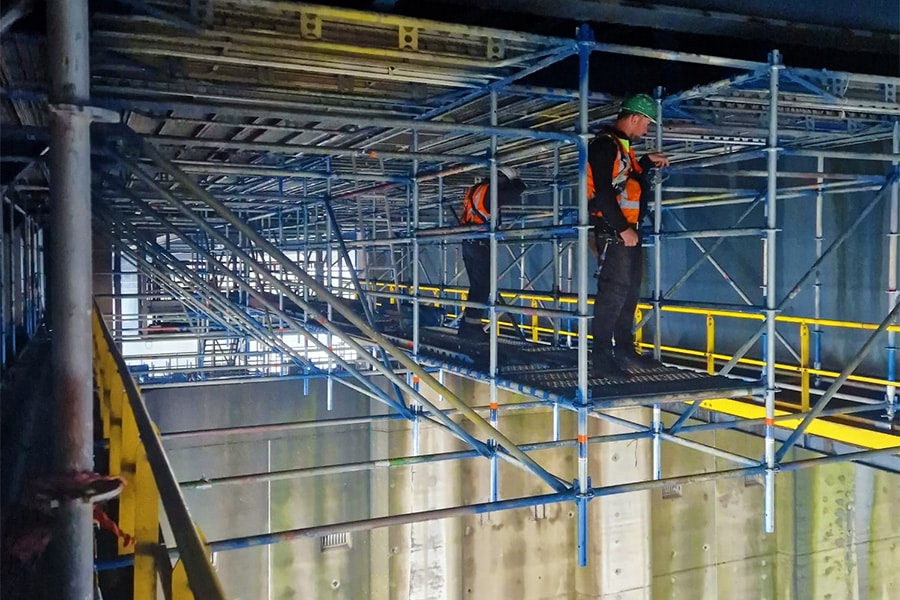

Implementation of the wind farm is in the hands of Hitachi-ABB, which is building the substation, Vestas as the supplier of the wind turbines and Windcombinatie Dura Vermeer-GMB, which is responsible for the entire substructure and infrastructure. Henk Ruiterkamp, realization manager at GMB: "To be precise, we are building the concrete piles with cast-in anchor cage, creating permanent crane stands for each turbine, providing the cabling and constructing all the roads to make the turbines accessible."

Permits

At 220 meters, the southwesternmost towers planned are the tallest. Ruiterkamp: "That is the maximum that can be built at that location. The other turbines have a lower tip height of 150 or 160 meters because they are in the approach route of Lelystad airport. You have to take many things into account and go through a series of permit processes before you can build something like that. Windmills also receive a temporary permit that takes effect the moment it is granted. So building quickly is essential if the BV wants to make a return. This is also one of the main objectives for all involved, where we obviously do not make any concessions on safety and the environment and also want to keep all stakeholders in the area happy. In short, our GMB slogan 'challenge connects' certainly applies." The Wind Combination is on schedule: the infrastructure is already in place, the substation is connected and the first wind turbines are standing June 2021.

Parametric designing

Parametric design is used for the structures of the foundations for the turbines. Bart Zevenhoven, junior structural engineer at Dura Vermeer: "That is a logical way of working if you have to design and build 91 foundations for four different types of wind turbines. You can see these piles as standard objects with the same shape and where the transfer of forces takes place in the same way each time. The differences are in the dimensions and in the soil conditions. With one of our software suppliers, we have developed a parametric tool that allows us to quickly calculate the required foundation dimensions and pile foundation for each location. In each case, we enter the set of CPT data of the local soil conditions and, based on the specified loads from the turbine, we can determine the required tensile and compressive bearing capacity of the foundation piles and check the requirements for the required rotational and lateral spring stiffnesses. These are unreal forces at a turbine like this, think moments to above 100,000 kNm."

Vibro-piles are driven for the foundations of the mills: 15 meters below sea level for the smaller models and up to 20 meters below sea level for the 220 meter high mills. The structures thus comply with the Eurocodes. The loads including safety factors, which are charged to the foundations, comply with IEC 61400-1. This is approximately comparable to consequence class CC2.

Individual interests

For now, the people of Dura Vermeer and GMB can still be found in the vast polders near Zeewolde. Ruiterkamp: "We are certainly still busy building here for the time being. But also taking interests into account. It is partly a complex project because you are working for a collective client, but you are working in the backyards of individual parties."

In 2022, Windpark Zeewolde will generate 850,000 MWh per year. Wind combination Dura Vermeer-GMB is using 43,000 m³ of concrete and 4,120 tons of reinforcing steel for the foundations and has constructed 44 km of new roads, as well as 338 km of 33 kV cable and 110 km of fiber optics.