Future-oriented distribution center requires specialty floors

The distribution center with a size of 46,500 m² has a maximum storage capacity of no less than 85,000 m² by means of racking and the possibility of adding (intermediate) floors at a later date. Van Berlo was engaged at an early stage by contractor Lowik Bouw to achieve optimizations in the floor and foundation design.

Since its founding in 1979, Van Berlo has become an absolute market leader in industrial and super-flat concrete floors. "We can completely unburden our clients," begins account manager Frank Louwers. "From pasture to anchor bolt. That starts with our own engineering department. Because we are at the table from the start of a project, we can think along in the design phase. In many cases, that results in a "smarter" floor construction, saving us - and thus our clients - time and money. Such was the case for the floor design of Kees Smit Garden Furniture's new distribution center."

Double floor solution

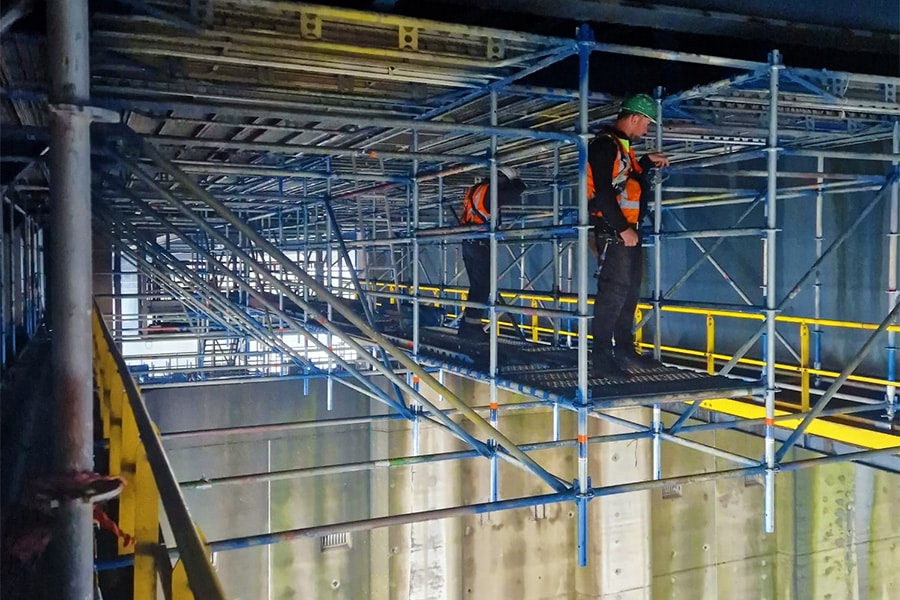

The foundation at the XL Businesspark in Almelo was uneven, Louwers continues. "Initially there were doubts whether the floor should be founded on steel or on piles. Since the request was for a super-flat floor and differential settlements will eventually affect the flatness and requirements, it was decided to found the floor on our Mini Vibro piles. And so it was carried out, with 8,621 Mini Vibro piles in total, accounting for a total length of 65 kilometers. For the floor itself, a "double solution" was chosen. On the one hand there was a high flatness requirement because of the desire for narrow aisles and induction-controlled forklift trucks, and on the other hand the garden furniture giant wanted to keep open the possibility of inserting two intermediate floors for order picking. To this end, additional piles have been installed in the ground. So it is truly a future-oriented building and extremely multifunctional in terms of layout. We provided all the floors, ranging from 24,000 m² of superflat floors to the floors in the other areas as being expedition, mezzanine and dock/load pit structures, amounting to a total of 46,500 m². 550,000 kilograms of reinforcement were applied and 7,600 m³ of concrete."

Low shrinkage concrete

Van Berlo has everything in-house when it comes to designing and realizing the total floor construction. Louwers: "We continue to constantly innovate and further develop our products to perpetuate our position as market leader. For example, we have now started research with our engineers and concrete technologists into the manufacture of low-shrinkage concrete. We are also well advanced in the integration of Tekla in our engineering department. The aim is to work out all floors and structures in 3D from now on. For the floors this may not be so exciting, but for the foundation and dock structures all the more so."