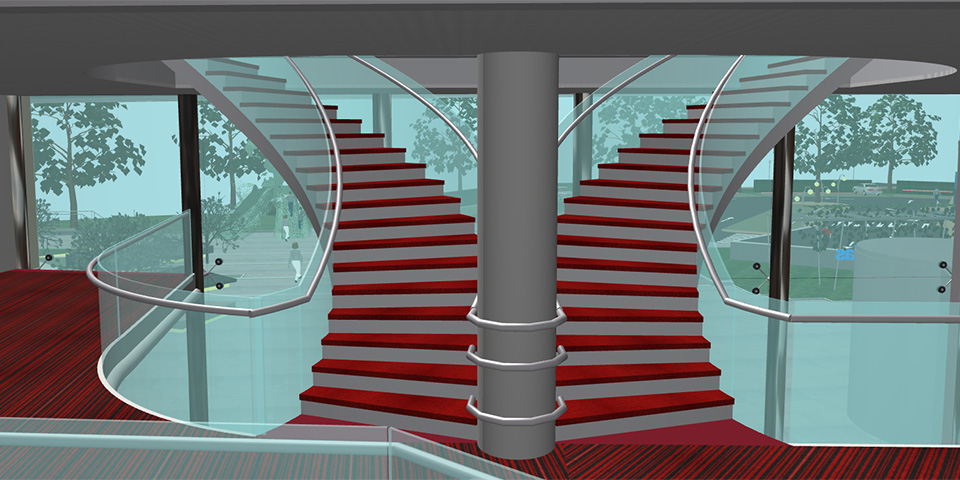

AFAS Experience center, Leusden | Striking white curved staircase

The white concrete stairs in the AFAS Experience Center are true eye-catchers. Sometimes they are slightly curved, other times they turn 270° on their axis. In all cases, it required a lot of technical ingenuity to produce the stairs. In the Netherlands, Lammers Beton is among the few concrete producers who understand this art.

The production of the white concrete stairs was prepared by the Work Preparation and Engineering departments at the Lammers Beton office. These made the calculations and drawings in 3D. In this way, as many errors as possible were tackled in advance. Then wooden stair moulds were made in mirror image. "This is where the practical challenges began," says Stephan Lammers, owner of Lammers Beton. "Because of the curved shape, the formwork had to be closed on all sides and thus provided with a counter-box. This was not only complicated, it also made the process less manageable. We were then no longer able to check whether the self-compacting concrete mortar - which we let flow into the molds through two small dump pipes - was sufficiently workable and stable and flowed exactly to where we wanted the mortar to go."

White self-compacting concrete

Because of the curved shape, the formwork had to be closed on all sides and thus be fitted with a counter-box

Still, in order to optimally control this process, Lammers Beton used the white concrete mix based on Aarlborg Portland cement in its production. Through its longstanding relationship with Aarlborg Portland, Lammers Beton is familiar with this white cement and has great confidence in its performance. "The self-compacting concrete mix compacts extremely well and is beautifully white," Lammers says. "For that reason, we dared to produce the curved stairs with it. Thanks to the team at Lammers Beton and the suppliers, we were able to deliver the curved stairs perfectly. The engineers and work planners did an excellent job."

No matter how many challenges the production of the stairs posed, all the stairs - 176 in all - came out of the formwork flawless in one go. With only a few minor corrections, they were ready for transport and assembly.