DEMAN

More than 60 years of crane construction

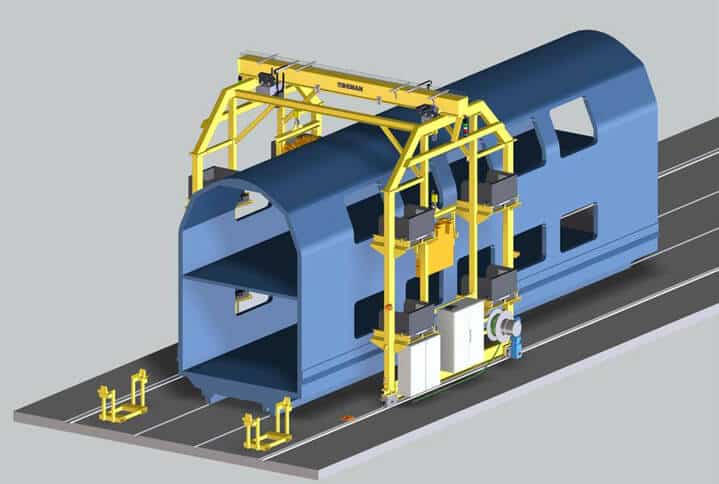

Construction Workhouses DEMAN has more than 60 years of experience in reliable and competitive lifting systems that increase the efficiency of your business operations.

DEMAN sets the bar high, always and everywhere. We choose quality from analysis and design, through production to after-sales service.

Today, there are virtually no solutions on the lifting technology market that cannot be found at DEMAN. Our know-how is an asset that you can use in your production process.

Engineering

A creative team of experienced engineers and designers understands your specific needs. Our team - in direct contact with you - conducts a thorough needs analysis. This is the basis of an optimally customized solution. In more than 60 years of crane construction, know-how has been built up, ensuring that you have a reliable, innovative and high-performance hoist.

Our in-house design office allows lifting equipment to fit flawlessly into your infrastructure. Even if it is only at the design stage. With total designs in 3D, we can exclude conflicts and evaluate safety risks together. This way of working together (possibly with external consultants) is guaranteed to be successful, right from the start!

Production

Local production by a driven team with many years of experience offers the possibility to work very flexibly, and allows the integration of different local services and goods. This makes us the ideal partner for co-production with your designated specialists for automation, bulk handling,...

Quality is guaranteed by various DIN and European standards and practices, including EN-1090 certification. But due to our local proximity, you can also ascertain the quality yourself simply by visiting our production site. You will find that we continuously strive for innovative and cost-effective production processes with integrated quality assurance.

Assembly

The expert assembly of a hoist is an essential and necessary step for its safe and trouble-free operation. This applies both to the hoists themselves and to the crane tracks on which overhead and gantry cranes travel. If assembly is carried out accurately and exactly according to plan, abnormal wear is virtually eliminated. The reliability and service life of the hoists is significantly improved. Unexpected downtimes are reduced to a minimum.

The precision (measuring) tools and customized attachments used by our technicians enable efficient and safe assembly. Safety is a primary requirement, even during assembly, which is carried out entirely in accordance with the requirements of a VCA* certificate.

Service

You want optimal availability of your lifting equipment, and thus a minimum of unforeseen downtime. Professional preventive maintenance at regular intervals is a (legal) requirement. And nobody is better suited for this than our technicians, who do nothing else year after year, and who receive continuous training on top of that.

With a REMAIN connection, we keep track of all parameters properly, and you enjoy substantial savings on operating costs. In addition, you can also enjoy our 24/7 emergency intervention service, which addresses a rare problem in no time.

The follow-up via REMAIN was started in 2001, and after 15 years it has become very clear that regular and professional preventive maintenance drastically reduces the number of unwanted downtimes. In addition, a lot of curative maintenance is not done after an undesired downtime, but at a well-planned moment, with a minimum of disruption to the production process.

Sustainability

“Moving to Green” is the name of a dynamic process DEMAN started in 2010.

We successfully achieve the reduction of our carbon footprint through a variety of actions that we address in three main themes:

- Saving energy

- Reducing emissions

- Sustainable products

If you would like more information on current promotions, please do not hesitate to contact us.