Innovation drive characteristic of market-leading experts in foundations and commercial flooring

With the production of a broad spectrum of monolithic finished concrete floors alone, Van Berlo does not stop there. Also in the preliminary stage, the company has everything on board to literally provide clients with a solid basis. Moreover, the flooring specialist from Veghel takes the necessary innovative steps in parallel on an organizational level. Reasons enough for an interview with commercial director Glenn Verhoef.

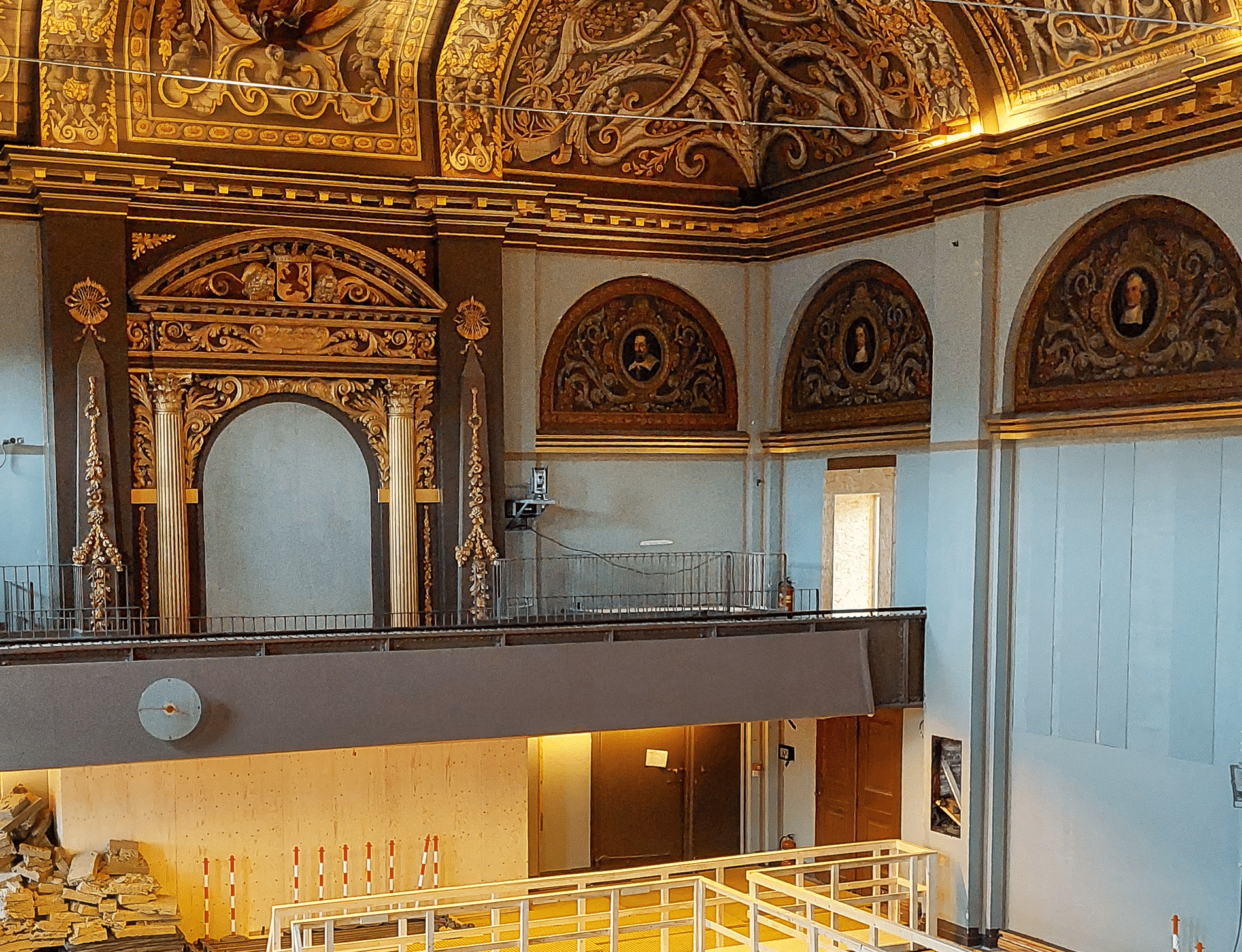

Installation of precast concrete elements.

Installation of precast concrete elements.

Producing high-quality, durable concrete floors is Van Berlo's specialty. On steel, on piles, jointless, hybrid or traditionally reinforced. Flat, super flat or liquid proof. Applied in small or large format within distribution centers, warehouses, parking garages and stores, among others. Choosing the knowledge and expertise of Van Berlo, market leader in the Benelux, is choosing a floor that fits. In any situation. "At the same time, in terms of substructure, we offer a number of welcome added values," says Verhoef. "For example, Van Berlo Engineering focuses on designing, calculating and drawing substructures. From Van Berlo Funderingstechnieken and Van Berlo Systeemfunderingen, we literally lay the foundation for everything that is located ónder the floor."

3D modeling

The expertise offered by Van Berlo is being followed up beautifully through an intense drive for innovation. "We strive to continuously improve our performance," says Verhoef. "For example, we are currently putting a lot of time and energy into 3D modeling of floors, foundations and pile plans. Especially for the latter, this discipline is very interesting, because with a sound 3D model you can prevent numerous clashes during execution. Think about the installation of sewers and the pulling of electrical cables. By delivering the complete foundation story in 3D, you exclude possible problems as much as possible. This service is therefore a valuable addition to our range of services."

Pouring the concrete floor with the Super Screed.

Pouring the concrete floor with the Super Screed.

Personnel initiatives

This also applies to two personnel-related initiatives. First of all, Van Berlo has had a real concrete technologist in the person of Marie-Louise Peters for the past year. "Marie-Louise collects all kinds of data from the concrete plants we do business with," explains Verhoef. "She then translates the information obtained into recipes for the concrete we use. Among other things, this takes into account the consistency class and the available aggregates, as well as local and weather-dependent conditions. This is how we ultimately arrive at the ideal concrete composition during the execution of our projects." The skill set required for this is scaled up by Allard Klein Onstenk, who recently joined Van Berlo as a company instructor. "Allard focuses on writing teaching modules so that we can raise the theoretical and practical knowledge level of the employees to an even higher level. All aspects of the profession are covered in detail. He also teaches our people how to properly use tools and resources. We are trying to get this training accredited over time, so that the certificates we obtain will carry some weight. We are also looking for cooperation with regional ROCs. Not only to promote our training, but also to propagate our beautiful profession to the next generation."

Text | Chris Elbers Image | Van Berlo

Featured image: Pouring the concrete floor with the Super Screed.