Unique reinforcement operation 'saves' historic Kaaibrug Klundert

The Moerdijk municipality has investigated three bridges that provide accessibility to the center of Klundert. After an inventory by Nebest, it was found that these bridges were overloaded in the built-up area. They were immediately closed to heavy traffic. Fully in line with the vision of the Municipality of Moerdijk to reinforce structures instead of replacing them, Nebest wrote a plan for the reinforcement operation. In particular, the reinforcement operation of the Kaaibrug is one to pass through a ring.

The Moerdijk municipality sees more and more opportunities in circular reuse and reinforcement of structures instead of demolition and new construction, says Arjan Deurloo, management consultant at the municipality. "In 2022, three bridges in the center of Klundert were benchmarked by Nebest against the new Eurocode standards for structural safety. Those verification calculations showed that the bridges were overloaded. An axle load restriction and a load limitation have applied to these bridges for less than a year now. Specifically for the Kaaibrug these are 10 tons and 45 tons respectively. Heavy traffic has been diverted since then. Only public transportation and emergency services have an exemption."

Most efficient solution

Such an obstruction is obviously not desirable for the accessibility of the center. That is why the municipality commissioned a variants study for each bridge to come up with a suitable solution. "For this, too, we engaged Nebest again," says Deurloo. "After all, they knew all the ins and outs from the verification calculations and have an awful lot of knowledge and experience with this kind of project. In addition, it is also a good party to work with." The variants study then concluded that the life of the Kaaibrug could be extended by at least 30 years by adding reinforcement to both the top and bottom of the bridge. "It turned out to be the most efficient solution in terms of sustainability, circularity and nuisance. And of course the financial picture was also taken into account," Deurloo adds.

Doubts about actual concrete quality

For the verification calculations, Nebest had enough with the available archive documents and scans of the Kaaibrug's reinforcement, for working out the reinforcements it was not enough. "To gather the actual concrete strength, we had concrete cores taken and tested in our lab. The concrete quality on the drawing was so low that we felt that the actual quality would turn out to be somewhat higher due to the ongoing hydration," explains Tim Pauli, structural engineer at Nebest. "And that turned out to be the case. In fact, the quality turned out much higher in practice, and that helped to limit the reinforcements."

Two pain points

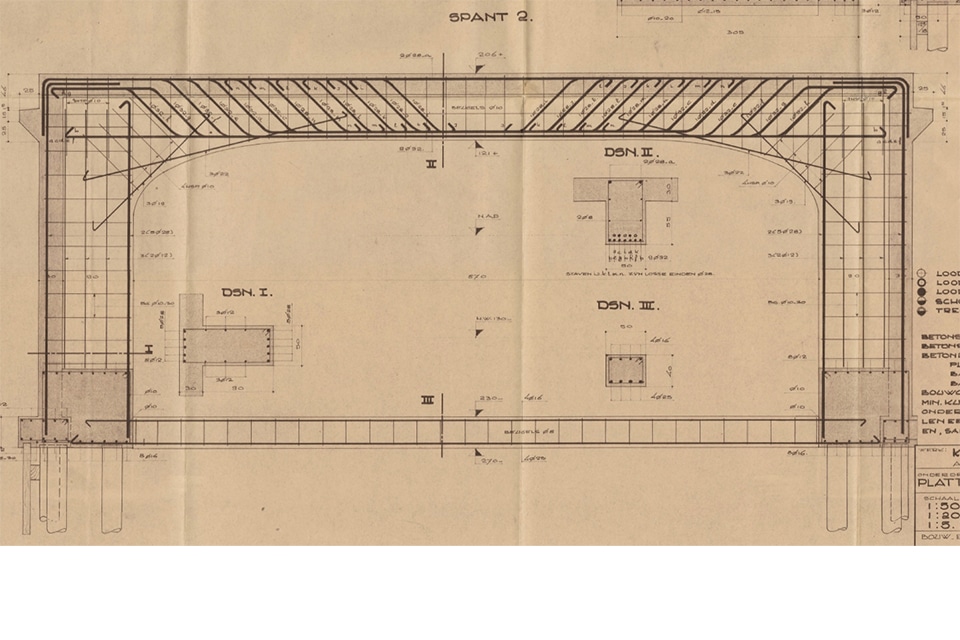

The bridge deck rests on three trusses transversely with cantilevers on either side for the footpath. The trusses are connected with tie beams to minimize horizontal displacements. "The truss functions as a portal structure consisting of columns and moment connections to the beam. The recalculations revealed two pain points," Pauli says. "At the force transfer in the transverse direction from the bridge deck to the trusses, the moment capacity of the reinforcement is exceeded, at the location of the edge trusses. This must therefore be reinforced. In addition, we came to the conclusion that the transverse force capacity of the column of the center truss leg was insufficient for the current traffic loads and must be reinforced."

Adding additional reinforcement

For the first pain point, Nebest devised a reinforcement measure in the form of adding extra top reinforcement in the deck. Pauli: "Using the technique of water scrapping, the bridge deck is 'peeled off' in phases and in sections of 1 by 1 meter each in order to create sufficient space. However, the additional reinforcement must also be partially anchored in the truss itself. Therefore, part of the truss will also be peeled off. Step by step, we are going to remediate surfaces, rebar and raise the concrete, with the bridge fully enclosed and partially underpinned. If all goes according to plan, this first reinforcement measure will be carried out after the summer."

Transverse force anchor

The second reinforcement measure is a bit more complex, according to Pauli. "Reinforcing on transverse force is quite challenging, especially since here we deviate from the traditional way of drilling an anchor through-and-through and anchoring on both sides. We're going to work with a transverse force anchor here. We will first drill a hole in the column of the truss leg, insert the anchor and tension it. This way we build a force arch and the anchor does not have to be secured at the rear. Given the construction, the latter is challenging partly because of the additional excavation work. Fourteen transverse force anchors of approximately 1.1 meters are installed per column. Thus, the center truss will soon be reinforced with 28 anchors. The edge trusses just met on transverse strength and that's just fine for the appearance."

Such projects are right up Nebest's alley. "A lot of aspects come together and that is where we distinguish ourselves as an agency. We have all the disciplines in house to manage such a project from start to finish," Pauli concludes.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Nebest BV.

Contact opnemen

Contact opnemen