Sustainability and concrete production go hand-in-hand

SBM's motto: sustainability and concrete production go together! And this can be seen in SBM's product range, as they have a number of specific solutions that reduce environmental impact.

Supermobile Euromix.

Supermobile Euromix.

Fewer traffic jams, less CO2-emissions (-25%) and a more homogeneous product to be processed. Take as an example the super-mobile concrete plants with capacities up to 170 m3 per hour that are usually deployed on a large construction and/or infrastructure project. The biggest savings are in the deployment of the number of truck mixers on a project and the distance they have to travel because the supply of sand and gravel usually remains the same in them. Supermobile plants are also increasingly being used as a temporary production option at the time when the company's own, usually fixed plants are being converted.

Within one day, using one crane, the super-mobile plant is set up and made ready for production. And after a production time, the plant is also dismantled and moved again in one day. Because the plant must be able to be moved frequently, it is characterized by a heavier construction method than, for example, the semi-mobile versions. Take SBM's cement silos, for example, which can be lifted by crane complete with foundation, thus guaranteeing fast positioning. Costs for relocation are therefore on average €50,000 lower than an average semi-mobile version. From three relocations onwards, the additional investment of a super-mobile plant compared to a super-mobile plant therefore pays off, quite apart from the higher residual values attached to super-mobile concrete plants.

Citymobile Variomix.

Citymobile Variomix.

SBM's City mobile plants are also a good example of a plant that has looked at reducing CO2-emissions, a more homogeneous product and timeliness of deliveries. The Variomix or Minimix are a good example of this because they are mainly used in inner-city projects where low m2-footprint is demanded and where high demands are made of concrete. Concrete mixers and concrete pumps are often not required, as the concrete is poured directly into the cubel of the tower crane and thus further processed at the construction site. Both variants have a small footprint (in m2), as space for installation is often limited within urban areas. Therefore, the standard version of both variants consists of only five transportable units within which all the technology to make a certified product is installed. One for the feed bunker, one for the control container with auxiliary material storage and three units for the plant itself. The last three units actually integrate the entire plant (from weighers to internal cement silo, from elevator to cube conveyor).

Of course, fixed installations are also needed, and for this SBM has several horizontal and vertical solutions in its range. Both standard and customer-specific when standard is not an option. Horizontal when there is a height restriction and size is not a problem, vertical when height is not a problem and possibly the available space is. Standard installations go up to 2,000 m3 aggregate storage and can accommodate two mixers with emissions of 6 m3 be installed.

Horizontal stationary concrete plant.

Horizontal stationary concrete plant.

SBM and Hunter Blending and Recycling Technology

SBM, Europe's number two concrete batching plant, has been represented by Jager Meng- en Recyclingtechniek since November 2018. For twenty years, SBM and Jager Meng- en Recyclingtechniek have been successfully linked in the concrete and recycling market.

Text | Hunter Blending and Recycling Technology Image | Jager Meng- en Recyclingtechniek / SBM

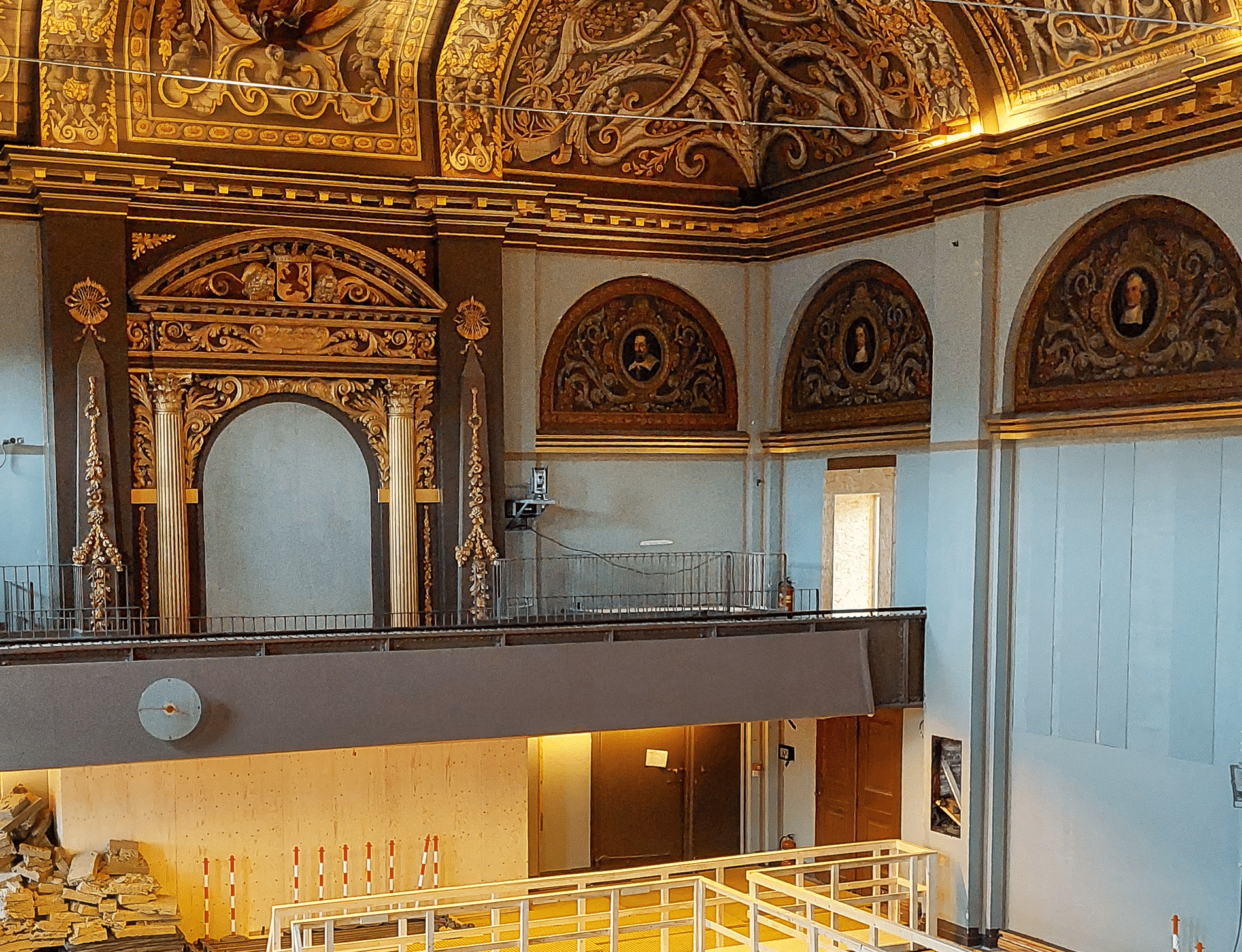

Featured image: Vertical stationary Towermix concrete plant.