2,500 tons of steel for new roof AFAS Stadium in Alkmaar

"Because we have all facets in-house, we can build quickly, efficiently and sustainably," emphasizes Engineering Manager Kees Oudshoorn. "Moreover, we can handle large and complex projects without any problems. The new, sustainable logistics center for DL Logistics Group and Jocotrans in Bodegraven, the new warehouses for Katoen Natie in Amsterdam and the new construction of Prologis DC2 and DC3 in Eindhoven are telling examples." Currently, ASK Romein is also involved in the construction of Jumbo's new logistics hub in Bleiswijk, as well as the realization of the new roof for the AFAS Stadium (AZ) in Alkmaar.

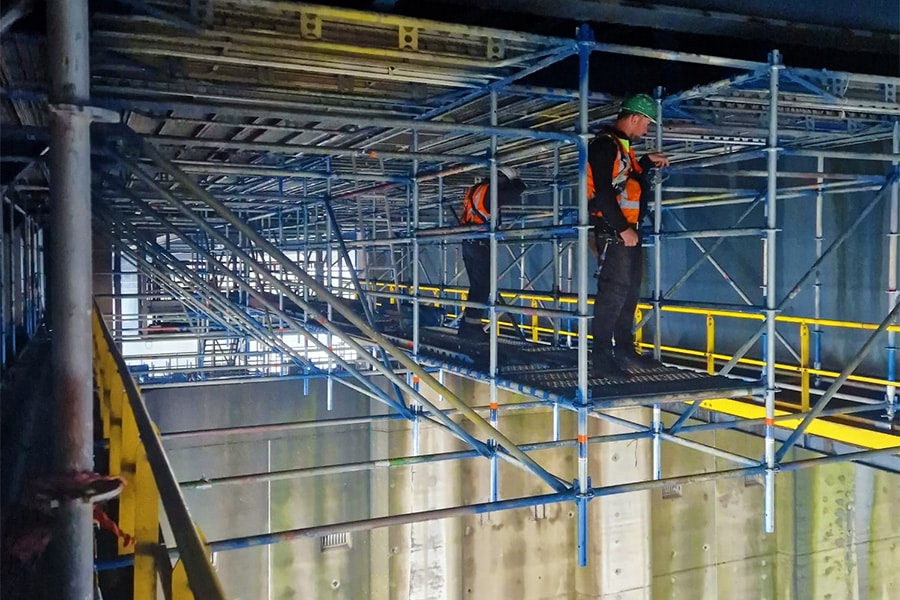

In August 2019, soccer fans were startled by violent images from Alkmaar: during a storm, part of the roof above the Molenaart stand collapsed. Fortunately, no matches were in progress at the time and no one was injured, but the damage was enormous. A combination of design flaws in the structural connections, welded joints that were too thin and previous storm damage appeared to be the underlying cause of the collapse. This emerged from research by structural engineer Royal HaskoningDHV, which then worked with Zwarts & Jansma Architects (ZJA), cost expert IGG and consultant The Stadium Consultancy to design a new stadium roof. BAM Bouw en Techniek and ASK Romein developed the architectural and structural design into an implementation design, after which the turnkey contract for the construction of the new roof was concluded last May. Within the partnership, ASK Romein is responsible for the engineering, production, preservation and assembly of the entire steel structure, with safety and quality being paramount, of course.

Huge truss with a span of 170 meters

"A completely new roof structure will be built around the stadium, separate from the existing building," Oudshoorn says. "The roof over the main grandstand will be supported by a huge truss, weighing 600 tons and spanning 170 meters at a height of 17 meters. This truss will be lifted over the stadium by two huge cranes and placed on four advanced support points, which must follow all the thermal expansion and movement of the truss. A hefty operation scheduled for the end of this year. The truss supports the roof of the VIP grandstand. For the other three stands, large crane trusses, or construction legs with a center-to-center distance of 9 meters and a cantilever of 30 meters on which the new stadium roof will be mounted, have been chosen. The new roof will be four meters longer on all sides toward the field, giving supporters more comfort in rainy weather."

Close cooperation

In total, about 2,500 tons of steel will be engineered, produced, preserved and assembled for the new stadium roof. To keep this process on track, several ASK Romein branches are working closely together, Oudshoorn said. "Where, for example, the engineering is carried out jointly by our people at ASK Romein Staalbouw in Roosendaal and Oostingh Staalbouw in Katwijk, the production of the overlays takes place at Hillebrand in Middelburg." The approximately 2,500 tons of steel are transported just-in-time to the construction site. In addition, all steel is provided with a four-layer coating, which makes the material as durable and weather-resistant as possible.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met ASK Roman.

Contact opnemen

Contact opnemen