Differentiate with a non-sexy product

Rebar for Van Gendt Hallen

You name it: producing and delivering hundreds of tons of reinforcing steel for a monumental 35,000 m2 renovation project in Amsterdam's city center. No problem for P. de Boorder & Zoon, even when a lot of improvisation is involved. "We always deliver quality and score well with our electrical equipment on construction sites like in Amsterdam."

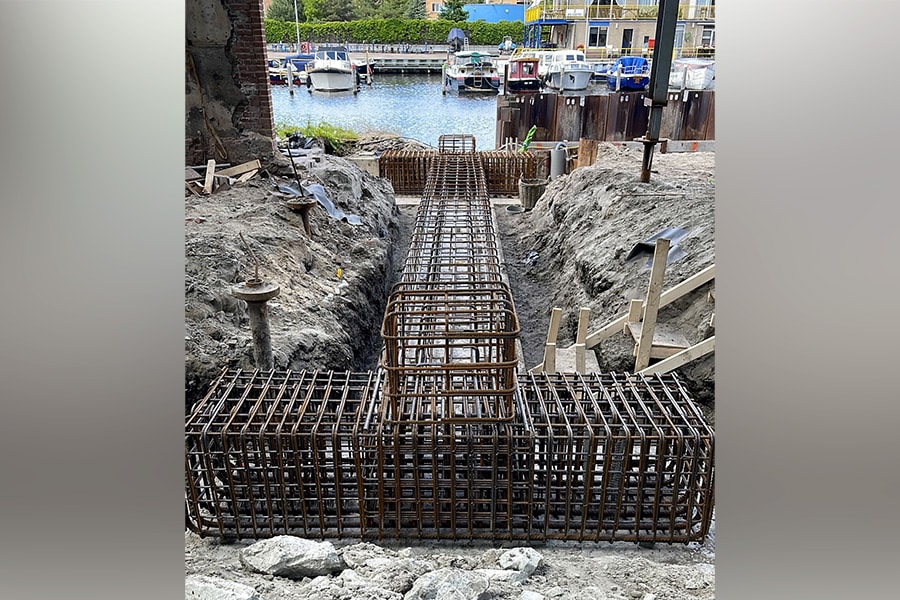

The transformation of the Van Gendt Hallen is one of the largest projects of its kind in the Netherlands. "It's five enormous halls, each with its own purpose and architectural interpretation, and that makes it so two years that we've been active here supplying reinforcing steel," Paul de Boorder outlines. "We supply all the reinforcing steel for the footings and supporting beams for the first floor floors, as well as all the reinforcement for the many steel plate concrete floors on the upper floors."

Experience

Concrete steel specialist P. de Boorder & Zn. saw the light of day in 1959 and has an impressive track record. "You have to earn a good name and that is not easy with a non-sexy product like reinforcing steel," continues the current owner. "It's usually purely about price and standing out as a company is not easy then. And then there are the cowboys who undercut the price and ruin the market. What we especially score with, besides our 65 years of experience, is that we think along as a partner for the best solution for the people on the shop floor. That really counts on a complex job like the Van Gendt Hallen, where every floor is different. Another plus is that we work with electric equipment as much as possible. Essential in an area where you can't get very far with fossil-powered equipment without an exemption."

Logistics

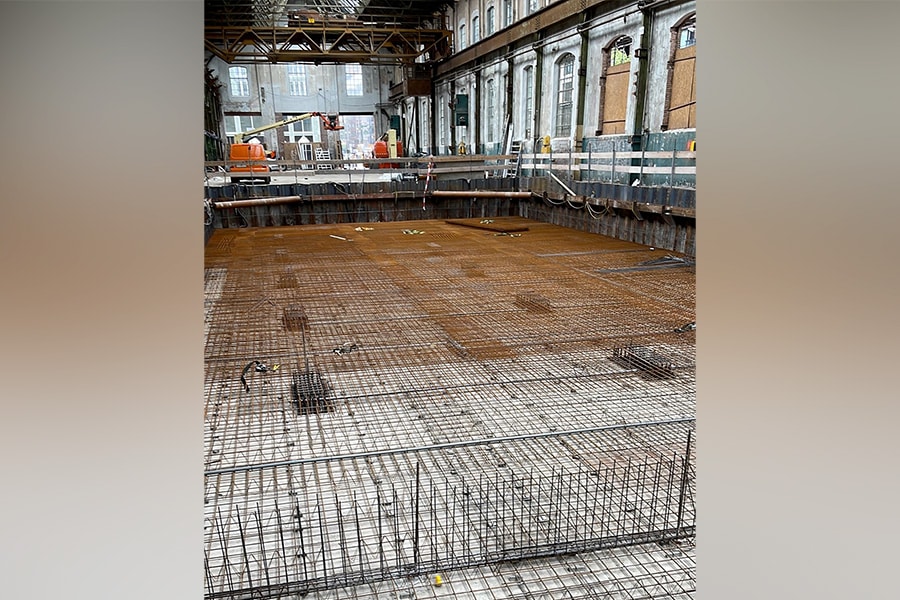

In a single hall, 80 tons of rebar disappears into a floor in this way. De Boorder: "Large equipment is not allowed there, so we had to cut the deliveries into 10-ton portions and deliver them by electric truck from a hub. For all the floors, this is quite a logistical planning exercise, to make sure that there are no delays anywhere. So far, this is going extremely well, in good consultation with the people at Van Gendt Hallen, Vic Obdam and SPS. We do the wickerwork ourselves, where possible prefab baskets are pre-produced in our cutting and bending plant, which is the easiest work for the people on site. Another factor is that large volumes and shapes cannot be handled due to the difficult accessibility of the site and buildings. But so far this too is going smoothly."

In work

P. de Boorder is handling the reinforcement of all the cast-in-place parts of the project. "All from 2D drawings," explains De Boorder. "At the time, we started with the heavy load-bearing beams that carry the first floor floors and the supports on which the steel structures for the storey floors stand. Included in the 25 cm thick screed is the piping for the concrete core activation. Pipes for the underfloor heating and cooling have been poured into all steel deck concrete floors. Here we laid reinforcing bars in the valleys of the floor and top netting on the steel." Later this year, P. de Boorder will lay the final meters of reinforcement for the Van Gendt Hallen. "A great experience to see the empty shell transformed into a multifunctional complex. I am proud that we were able to contribute our bit of steel to this."