Foundation repair and reinforcement of the Binnenhof with grout and gel

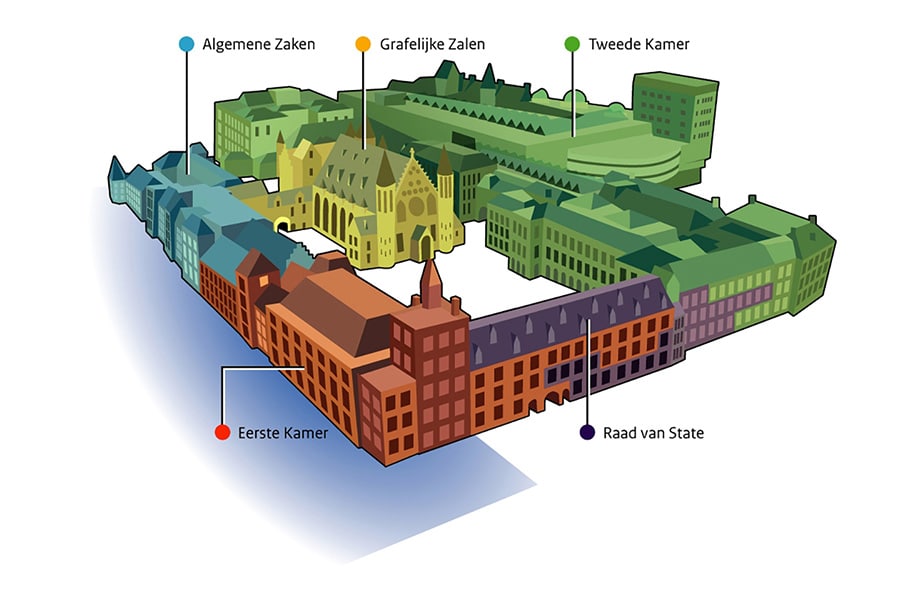

The renovation of the Binnenhof is a very large and sometimes extremely complicated operation. The complex, covering some 90,000 m2, consists of a series of buildings ranging from 35 to 800 years old and is full of surprises. These are often found underground, where archaeologists have been working for years on numerous excavations and excavations. This fifth episode in the series about the Binnenhof also focuses on the work being done underground. In this phase of the project, foundation reinforcements are being carried out in phases and at various locations. These are related, among other things, to the construction of a basement under the square in front of the Ridderzaal and large trenches for various facilities for different buildings around the Ridderzaal. But they are also related to the poor condition and unknown location or condition of many foundations and structures.

The modernization and sustainability improvements to the Binnenhof involve the installation of many new systems. Deep trenches are required on the site in order to connect all the buildings to the new facilities. Digging next to old buildings can affect their foundations. To prevent potential damage, various techniques are being used to reinforce the foundations.

Bows

The Heijmans Burgy construction consortium, responsible for the Senate and Council of State cluster, has now reinforced the arches of the galleries around the square. To this end, tubular piles have been placed in the ground next to the arches. Steel beams have been welded to these piles with jacks that hold the arch construction in place. Electronic level measurement (Fides) allows settlement during the excavation work to be monitored accurately.

Knights' Hall

VSF, Van Hattum en Blankevoort's foundation company, is currently working on a completely different technique around the Ridderzaal to protect this 13th-century (!) building from unwanted subsidence. Project manager Jens de Vries explains the intention: “Archaeologists must be given the opportunity to investigate what is in the ground. Soon there will be a trench around the Ridderzaal, which will make it impossible to access the remains of old foundations and structures. To make them accessible, they will have to be excavated. First, however, the foundations of the Ridderzaal will have to be stabilized. The Binnenhof complex, especially the oldest parts, is largely not built on stilts but is founded on steel on an old beach ridge. We stabilize it with hard gel injection, a two-component technique in which a water glass and hardener are pumped into the sand layer under low pressure.

This is done very precisely through holes in pre-placed sleeve pipes that are placed under and next to the foundations of the count's halls. This creates a temporary mass of sand grains and injection material, which forms a structural ground body for reinforcement. We drill relatively small holes to place the tubes. It is inevitable that these will also pass through old building remains, but the archaeologists are primarily interested in what is there and that they can document it. It doesn't matter if old building remains are slightly damaged locally if we can preserve the building itself, because that is the most important thing. For this purpose, a test section was first drilled and coordinated with the archaeologists.”

Hard gel injection

In foundation engineering, the drilling and injection team first uses fully electric equipment to insert a 114 mm diameter drill pipe with drilling fluid. A sleeve pipe is then lowered into this, which has a perforated hole every 30 cm, covered with a rubber sleeve. The drill pipe is then pulled out and the drilling fluid is allowed to harden to fix the pipe in place. A few days later, an injection hose is positioned in the sleeve pipe. Via the so-called packer at the end of the hose, with an inflatable segment in front of and behind the injection nozzle, a predetermined volume of hard gel is pumped upwards from the lower sleeve. This forms a sphere with a certain diameter in the ground around the sleeve. Then it is the turn of a higher sleeve, until stacked spheres form a column. Overlapping columns can be used to create a wall or a solid structure. By monitoring the pressure, the operator can determine whether a sleeve is in sand or stone. “All collars and pipes are stored in 3D in our system, and we know exactly how much we are pumping in at each point,” says De Vries. “We retrieve the liquid components from storage containers on site, where they are also mixed and pumped through.” All registrations and quality controls also take place there.

Sandy soil

Hard gel injection in monuments is a delicate operation, but VSF has a lot of experience with it. De Vries: “We recently applied this proven technique with sleeve pipes at other locations in the Binnenhof complex, as well as at the Mauritshuis and Paleis Het Loo, because it is very suitable for situations with sandy soil in which a monument or structure must remain stable.” The gallery and walls of the House of Representatives building have also been reinforced with hard gel. In addition, VSF will probably use both the injection technique and the jet grouting technique for the construction pit of the new entrance to the House of Representatives on the Hofplaats and the deepening of the elevator shaft of the Press Tower.

Senate

On the other side of the Senate building, Keller Funderingstechnieken cleared the work island in the Hofvijver at the end of October. Since June, a complete jet grouting plant had been located there. Heijmans called in Keller Funderingstechniek to reinforce the foundations of the Senate. At the beginning of last year, Keller was already active at the Stadhouderspoort of the Binnenhof. “An advanced project: the gate had to be deepened so that freight traffic and heavy equipment could pass underneath it towards the square in front of the Ridderzaal,” says Marcel Mertens, Benelux manager for Keller Funderingstechnieken. “Next year, we will start work on the Council of State and Middenpoort.”

Soilcrete®

Keller Foundation Techniques, global market leader in soil improvement and foundation reinforcement, opted for a jet grouting technique developed in-house for the various sub-contracts for the Binnenhof. Mertens: “Soilcrete® is a method of using jet grouting technology to create all kinds of shapes underground. For example, we formed slats under the Senate and Stadhouderspoort by moving the spray head back and forth at a limited angle, creating a triangular shape when viewed from above. A series of slats then provides support for the structure above. Once this has completely hardened, we fill the spaces in between with grout. If you were to do this in one go, the building could subside.”

Crawl through, sneak through

Jet grouting in and around a centuries-old building is not exactly easy. “That's why a lot of preparation and research is required beforehand,” Mertens continues. “It is also a sensitive building with many defects. That's why it has been monitored entirely with hydrostatic level cells, or hose water levels, in addition to the electronic measurements taken by Fides. The facade along the Hofvijver has been reinforced with thirty boreholes from a work platform.” Inside, it was a bit more complicated. “The ground floor of the building consists of a series of crawl-through spaces, each one smaller than the next. In addition, excavation under the floors revealed the old foundation wall, which shows that the facade of the building was once several meters further back. We then laid 10 cm thick concrete working floors in all rooms, which also temporarily absorb the forces of the walls. Core drillings were made in these floors at the correct positions for the subsequent jet grouting. For this, we used a compact KB1 machine that could fit through all the narrow corridors. It is still an art not to damage anything in the building or the machine. You have to move back and forth a lot because you can't finish a room in one go, simply because the grout has to cure.”

Return cash

A complete grout installation was set up on the Hofvijver platform for this operation. “Everything was done twice,” emphasizes Mertens. “In June, there was still a bridge over the pond to the platform, but that has since been removed. So replacing a broken pump was not an option, which is why everything was done twice.” The return slurry also required a solution. “Freight traffic is very difficult in that area, and you want to keep it to a minimum in that part of the city center. That's why we devised a way to collect the mortar in a 23-cubic-meter container. This was placed on a specially made trestle above the Stadhouderspoort passageway. A stirring mechanism prevented the mortar from hardening. The mortar was removed with a suction truck within four hours. This saved a lot of space, time, and money in terms of logistics.”