KANN GmbH Baustoffwerke, Bendorf| Manufacturer of concrete products modernizes various production facilities

A big step in the professionalization of the concrete industry

The development of innovative solutions, the optimization of existing products, outstanding quality at every level, customer-oriented service, high productivity and efficiency, short and reliable delivery times ... these are important concepts for anyone who wants to run a company successfully today. KANN GmbH Baustoffwerke, a German manufacturer of concrete products also attaches great importance to these key words. This is why the company is investing in the modernization of various production facilities all over Germany. In close cooperation with UBO Engineering, four projects have been implemented in recent years that meet the latest standards in terms of technology, automation and working conditions.

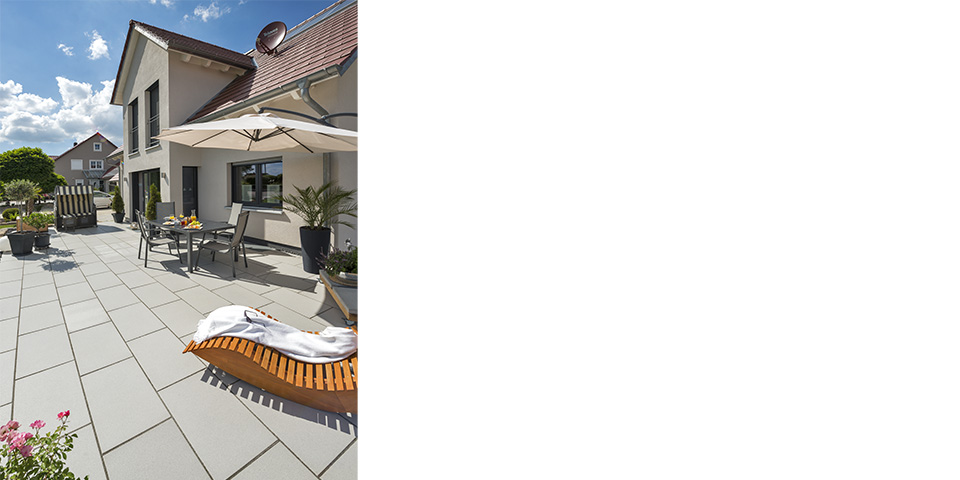

KANN's range includes high-quality concrete bricks for a wide variety of applications, as well as patio tiles, fences, stairs, walls and dikes.

KANN, founded in 1927, has become a specialist in its field through targeted acquisitions and thoughtful investments. "We are a manufacturer of concrete products with twenty-two production facilities and customers all over Germany and in neighboring countries," says Director of Engineering Matthias Liersch. "Our product range includes high-quality concrete blocks for the most diverse applications, as well as patio tiles, fences, stairs, walls and dikes. Thanks to our system families with color- and surface-matched products, we simplify the task of architects and building owners."

Modernizing production facilities

The name KANN is synonymous with the highest quality, sophisticated design and a high degree of individuality. Although the company has many years of experience, it comes down to always keeping up with the latest trends. Because innovation and design are also central in the construction industry. This is why the company continuously invests in the development of innovative solutions, employee training and the construction and renovation of production facilities. Among other things, the KANN Group opened new plants in Urmitz and Kaltenkirchen for the production of concrete tiles and concrete bricks respectively. Other projects include the modernization of production in Schermbeck and the planned renovation work in Hassfurt, for which the layout is already available.

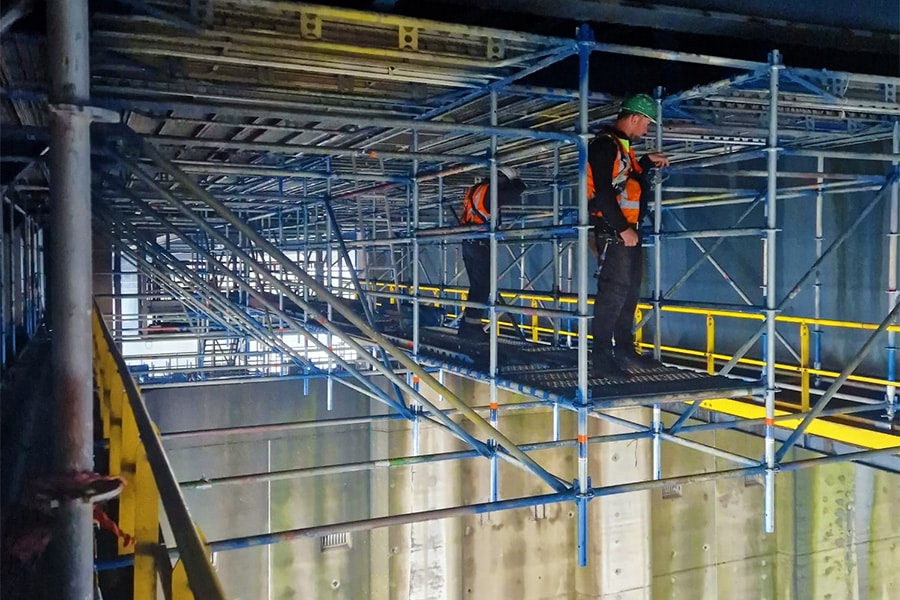

A state-of-the-art, fully automated production line is at the heart of the plant at the Urmitz plant. The concrete is mixed there in a new mixing and dosing system supplied by UBO Engineering.

UBO Engineering as a partner

"These projects have one thing in common: the layout was designed by KANN employees with a clear focus on productivity, efficiency and quality," explains de Liersch. "We had formed an idea in advance of what the layout could look like and which machines were needed. In the search for a suitable partner, we ended up with UBO Engineering. After visiting several production facilities, we decided to work with this specialist from the Netherlands and the firms Hess Group and SR-Schindler, both from the Topwerk Group."

KANN opened a new plant in Kaltenkirchen with storage space for the production of concrete bricks.

A state-of-the-art, fully automated production line is at the heart of the plant at the Urmitz plant. The concrete is processed in a new mixing and dosing system supplied by UBO Engineering. The aggregates for the overburden concrete come from twenty-two specific silos for such substances and another twelve daily bunkers, which are filled based on production. Six silos for aggregates were integrated for the components for the bottom concrete. The production of the tiles takes place in two Hermetik presses. After storage in a special air-conditioned room with separate humidity and temperature control, the tiles are refinished and post-treated on a surface treatment line with grinding machine and blasting unit. In addition, a coating machine and a modern packaging unit with industrial robots were also provided.

"The plants in Schermbeck and Kaltenkirchen differ thoroughly from the construction in Urmitz. A high-performance machine from the company Hess produces the concrete bricks. The supply of raw materials is via a vertical VHV conveyor belt, which transports the materials unmixed and 'clean,'" says Liersch. "The bricks are dried in an air-conditioned drying room, after which they are refinished and post-treated on state-of-the-art finishing systems, including a special brushing machine. Finally, there is also a production line for concrete wall elements and retaining walls."

In Kaltenkirchen, a modern high performance machine from the company Hess takes care of the production of the concrete bricks. The raw materials are fed in via a vertical VHV conveyor belt, which transports the materials unmixed and "clean.

Layout, design and technology: everything is 'TOP'

The KANN team is extremely satisfied with the quality of the installations as well as the cooperation with UBO Engineering. Layout, design and engineering are top notch one by one. "We have been one of the leading suppliers of machines and installations for the concrete industry for more than 80 years. Thanks to our wide range and experience, we can offer a suitable solution for almost every project. We have been providing customized solutions for customers in the Benelux for years, but in recent years there has also been an increasing demand from Germany," says Michel Bregman, Director-owner of UBO Engineering. "At KANN, they already had a picture of the layout and machines themselves. In close cooperation, we then conceived, developed and built each project. We also took care of the assembly and automatic control of the machines and the mixing and dosing systems. Great attention was paid to efficiency and flexibility, as well as to the reduction of energy and water consumption. With these plants, KANN takes a substantial step towards professionalization of the concrete industry and for UBO they are one by one reference projects for our customized solutions for the concrete industry."