Kieldrecht Lock, Antwerp | Two new bridges for the Kieldrecht Lock

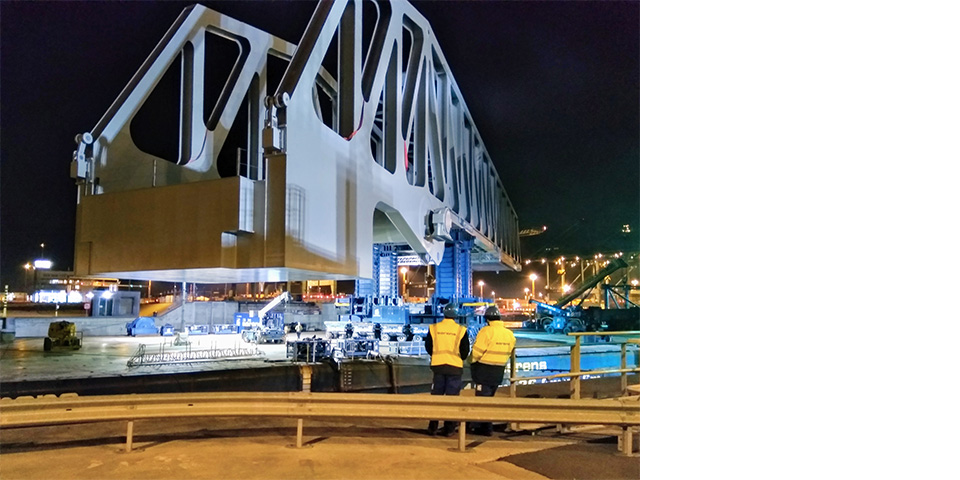

Finished bridges on one pontoon from Ghent to Antwerp

In July 2019, the Kieldrecht lock will have been in operation for exactly three years. Four bridges were planned when it was built, but only two were installed when it was opened. Now the THV Kieldrechtbruggen, which unites the firms Aelterman, Engie Fabricom and Hye, was commissioned by the nv Deurganckdoksluis to build and install the two remaining bridges in order to simplify and improve the flow of traffic and shipping in the port.

Each bridge is 100 m long, 15 m wide and 21 m high, weighs 1,500 tons and has two lanes of traffic. The fully finished bridges were transported together on one pontoon from the Kluizendok in Ghent harbor via the Ghent-Terneuzen Canal and the Westerschelde to the Waasland harbor.

The Kieldrecht Lock is the largest in the world and the original plans called for four bridges. However, only two combined rail and road bridges were completed in the first phase. Moreover, until now, the railroad was only used for internal transport between the various container terminals. In order to achieve a smoother traffic flow, the nv Deurganckdoksluis decided to issue a new tender for the construction and installation of the two remaining bridges. Unlike the existing bridges, which were built in China, the contract now went to the Belgian THV Kieldrecht Bridges.

The bridges were assembled at the Kieldrecht lock in three weeks, limiting disruption to shipping. Now they are in a vertical position until they are put into use this summer.

Clear division of labor

The tasks were clearly divided in advance. Aelterman realized the steel structure, while Engie Fabricom took care of the electromechanical installation. Hye had to ensure that the bridges could be perfectly connected to the concrete structure of the existing basement. "We started building the steel structure in the summer of 2017. The steel plates were burned, creating the right pieces, which were then put together like a puzzle. As with all other projects, this was pure customization," explains project engineer Frederiek De Preetere of Aelterman. "In the fall of 2018, the steel structure was ready and Engie Fabricom began the electromechanical installation. The shafts and bearings were mounted as well as all the electrical lines and the elements for navigation, such as the signaling. The bridges were also equipped with the guard rails and road surface."

The partners Aelterman, Engie Fabricom and Hye of the THV Kieldrecht Bridges realized a feat both for the construction of the bridges in the workshop and in the preparations on the site itself.

The almost identical bridges consist of a lot of heavy elements, even up to 20 tons each, which is very unique for a bridge. They are driven by three 200 kW hydraulic pump groups and two hydraulic cylinders with a diameter of 0.9 m, a length of 15 m and a weight of 43 tons. Moreover, it was not obvious to accurately integrate the 1,400-mm-diameter shafts in one attempt. After the structure and shafts were brought to the correct temperature, the elements were slid together, after which the pieces were allowed to cool and heat up again, respectively.

THV Kieldrechtbruggen was commissioned to build and install two bridges at the Kieldrecht Lock. The giant steel structures are 100 m long, 15 m wide and 21 m high and weigh 1,500 tons each.

Hussar

The bridges were fully assembled at Aelterman in the Ghent Kluizendok. At the same time, the partners also carried out the preparations at the Kieldrecht lock. Engie Fabricom assembled and tested the electrical and mechanical parts for the immediate coupling of the bridges. In turn, Hye provided the modifications to the concrete structure of existing cellars. Using hydrodemolition, the demolition or blasting of concrete with water under ultra-high pressure, the superfluous concrete was removed without damaging the reinforcement. "The construction of the bridges was a unique project, but the transportation was also a feat. Bridges are usually transported in parts and assembled on site, but on this project the bridges were shipped in one piece. A self-propelled modular transporter with sixty axles and two hundred and forty wheels placed the bridges on a pontoon toward Kieldrecht Lock," De Preetere points out. "In early April, the bridges were installed. We were given only three weeks for assembly. Afterwards, the bridges had to be put in a vertical position so that shipping in the Kieldrecht lock was hindered as little as possible. The bridges will remain like this until they are put into service in the summer."