Self-climbing formwork system puts deadline within reach

It did require ingenious formwork systems to build the tower within the 18-month time limit.

The Silver Tower has 8 underground and 32 above-ground floors including 2 technical floors. Yet only 18 months stood for construction of the tower. And that while CIT Blaton had to deal with other major challenges. For example, the Silver Tower was erected in the heart of Brussels, which lacked any space to set up a construction site, install a tower crane or store building materials. This required tightly organized logistics. In addition, the design - for example at the void above the entrance - required solid support solutions. Thanks to formwork methods from PERI, the 137-meter-high Silver Tower was nevertheless completed on schedule.

Complex formwork and support solutions

As soon as the order was a fact, PERI's engineers designed the formwork in record time. Not only did the formwork had to be shaped correctly, the supply and removal of the formwork elements also had to be possible in the tight working area. This made the designs very complex. But finally, there stood the ACS climbing formwork (Automatic Climbing System) from PERI with which the workers could safely climb without a tower crane and with which the contractor could raise one floor every five days. With no other formwork system could the contractor have managed this fast construction pace.

Ready-made on the construction site

Production of the custom formwork took place in the workshops of PERI in Schijndel and CIT Blaton. A large part of the formwork was also already assembled here, so that they only had to be put together at the construction site. This meant considerable time savings for CIT Blaton. In addition to the ACS climbing system, many other systems from PERI were used on the construction site, including the VARIO GT 24 Carrier wall formwork, the SKYDECK slab formwork, VARIOKIT engineer kit, PERI UP Flex Stair 75, PERI UP Flex rebar scaffold and MULTIPROP aluminum braces.

Fast. Cost effective. Expert

"PERI's ACS climbing system is light, good and practical," says Yves Uyttenhove, project manager at CIT Blaton. "Thanks to the climbing boxes, we were able to meet our deadline. The turnaround time of the formwork was minimal and we were able to make significant savings by not having to use an additional crane. In addition, we got to know PERI as a competent partner. The engineers laid the solutions to very complex problems in notime, fitting within the regulations for construction sites and core formwork in tower buildings."

Flexible formwork

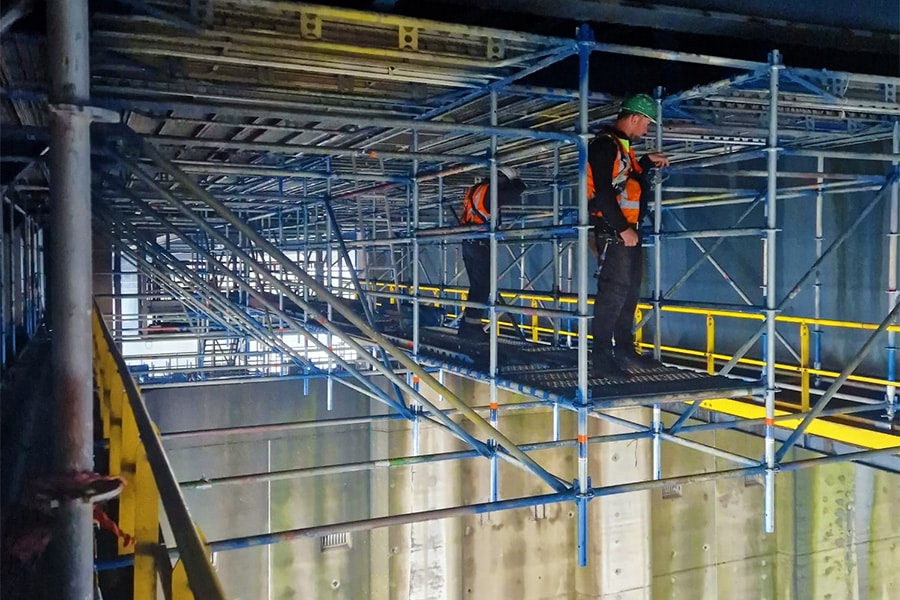

For the Silver Tower, the ACS system was designed so that both the thick walls in the lower levels and the thinner ones in the higher levels could be poured with the same formwork without significant modifications. This also saved time and money. The climbing system featured a closed work platform, in which the formwork was located at different levels and suspended below an upper work platform. This created more working space and made execution easier.

Versatile in solutions

Other systems also provided solutions to the formwork challenges. For example, SKYDECK floor formwork was used for the stability and strength of the tower on the 16th, 17th and 18th floors. To support the 24 inclined columns on the first floor, the VARIOKIT solution was used, and to ensure worker safety, PERI UP stair towers were built. "PERI had a solution for all problems."