Sint-Pieters-Woluwe Stormwater basin | Innovative technique with tunnel boring machine limits impact on surroundings Tubular stormwater basin should avoid flooding

When it rains heavily, people hold their breath in certain areas, because if things get a little bad, the streets are flooded and the water runs into homes. This is also the case in and around Woluwe-Saint-Pierre. That is why client Vivaqua commissioned THV Grootveldlaan (BAM Contractors, Wayss & Freytag and Denys) to build a tubular rainwater basin with a storage capacity of 8,000 m³ under Grootveldlaan. The contractor is using an innovative technique based on a large-diameter underground tunnel combined with a pump pit, access shaft and overflow. Thanks to this underground installation, the impact on the environment remains limited.

Due to climate change, we face more frequent sudden heavy rainfall, making storm water management a top priority in Belgium as well. When it pours in and around Sint-Pieters-Woluwe, the sewers in the Struybeeck Valley have trouble swallowing the water. Consequently, streets flood and cellars flood. That is why the rainwater basins Grand Prix (7,000 m³), Herendal (7,000 m³) and Stockel (3,000 m³) were built in the past. "These basins are designed to temporarily store large volumes of water, allowing us to regulate flows in sewers, avoid flooding and control discharges into the natural environment," says Dirk

Derycke, Division Manager of Tunneling & Drilling at Denys. "During heavy rainfall, sewage flows into the basin. After the downpour, the water is pumped back up to the sewer."

THV Grootveldlaan first created a sump pit with secant piles and a floor slab in reinforced underwater concrete. The tubular stormwater basin followed in a second phase.

New technology with underground tunnel

However, the risk of flooding in the area remained high, so Vivaqua decided to build a new basin with a storage capacity of 8,000 m³ on Grootveldlaan. The THV Grootveldlaan, which includes BAM Contractors, Wayss & Freytag and Denys, was awarded the contract. "Due to the dense construction here, it was difficult to integrate above-ground wells. A large-diameter tunnel combined with a sump pit provided the solution," Derycke points out. "After all, thanks to this innovative technique, the visible impact for the surroundings remains very limited."

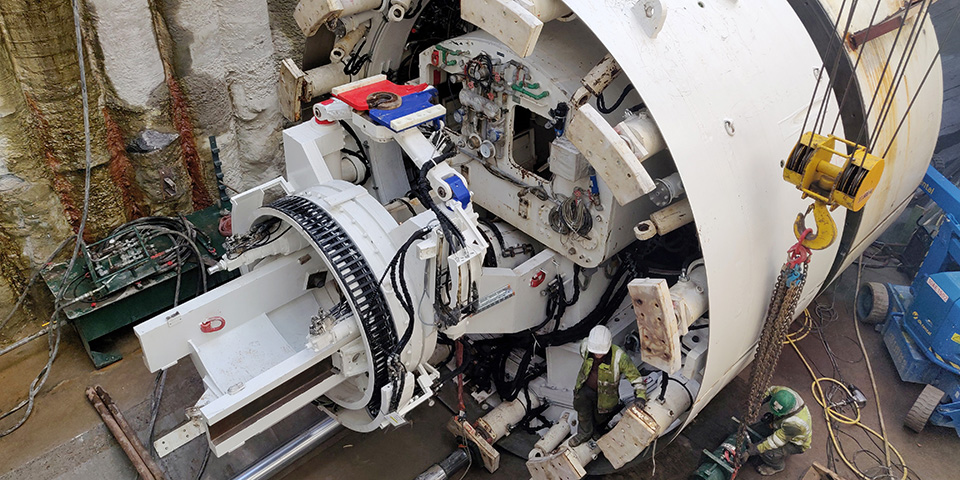

Site manager Sander Cambron explains the project: "Last year we created a pump pit 17.40 m long, 10.90 m wide and 12.25 m deep, equipped with secant piles 16 m long and a floor plate in reinforced underwater concrete. In February 2019, we started assembling our tunnel boring machine named Petra, which is now being used to drill a 375 m long tunnel with an inside diameter of 5.20 m. For the assembly of the tunnel walls we are using 310 prefabricated segment rings produced at our subsidiary in Oelegem. At the beginning of next year, at the end of the tunnel there will be another access shaft 15 m deep, which will be used for inspection and ventilation, among other things. By the middle of 2020, the connection to the sewer network will follow and the sump will be finished."

Tunnel boring machine Petra, specially adapted for this task, must drill a tunnel 375 m long with an inside diameter of 5.2 m.

Quite a challenge for the engineers

A lot of above-ground rainwater basins have already been realized all over the country. Nor is this the first tubular rainwater basin in Belgium, but it is the largest. "Our tunnel boring machine was first used for a project in Algeria and has been specially adapted for this tunnel," concludes Derycke. "Unlike other installations, we work with a short pump pit. The tunnel also has an inclination of 1%, so no sludge remains. Consequently, the project in Sint-Pieters-Woluwe is quite a challenge for our engineers." ν