Standardizing artworks with IFD

Replacement and renovation Cruquius bridges

For the province of North Holland, the replacement and renovation of the Cruquius bridges is an important pilot project. The ambitions in the field of sustainability are high and this should result, among other things, in the standardization and sustainability of as many infrastructure projects as possible. After all, the Cruquius bridges are not only being built in a circular, energy-neutral manner and as low-maintenance as possible, they are also a pilot for how bridges can be made industrially flexible and demountable (IFD) in the market.

The entire province has more than 14,500 structures, from culverts to large bridges, so there is a lot to be gained there with IFD. The engineering structures are owned by the various managers and a large proportion of the bridges and viaducts will come of age almost simultaneously in the coming decades. The province is therefore the initiator of 'Samen Slimmer Renoveren en Vervangen' (SSRV), in which various municipalities, Rijkswaterstaat, ProRail and the Transport Region of Amsterdam are working together on the replacement and renovation task they all face in the coming decades.

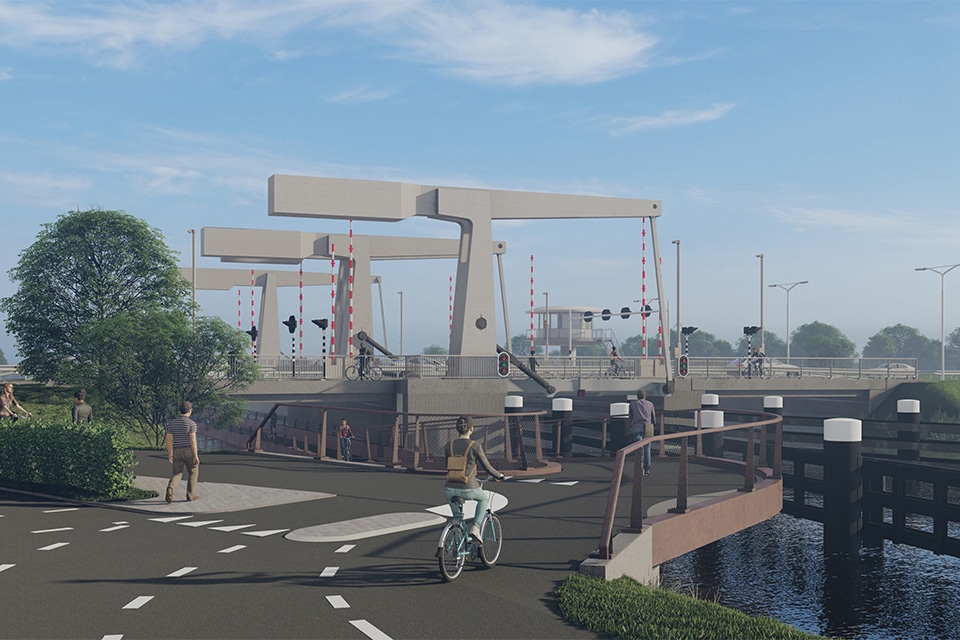

The village of Cruquius lies on the ring canal of the Haarlemmermeerpolder and owes its name to the famous pumping station built in 1849. Less than 30 meters away are the Cruquius bridges. They form the intersection between the Ringvaart and the N201, the connection between Heemstede and Hoofddorp that is especially important for cyclists (schoolchildren) and buses. The artwork consists of a drawbridge from 1932 for traffic towards Heemstede and a wider drawbridge from 1972. The old bridge is currently being replaced, the second one completely renovated.

Collaborative programming and procurement

In the tender, won by the combination Van Hattum en Blankevoort - Hollandia Infra, sustainable, circular, energy-neutral and IFD are keywords. The first three find their origin in the Environmental Vision HN2050, the underpinning of the province's sustainability ambitions that have also been translated into the coalition agreement. "IFD is mainly about standardization and the savings in time, nuisance, manpower and money that this can bring," says Jeroen Olthof, Deputy for the province of North Holland and responsible for mobility and accessibility, among other things. "We already do sustainable procurement as much as possible, IFD is the next step. The problem with artworks is that each object is more or less unique. If you want to replace something, it requires a unique component each time. Given the amount of artworks that will need replacement or renovation in the future and the scarcity of personnel, raw materials and other resources, a different approach is necessary. With the SSRV initiative, we want to combine knowledge, strengths and finances to jointly program and tender projects for this enormous task. We are talking about billions of euros, so there is a lot to gain there."

Families

Those gains are both in the design and realization phases and, over time, in management and renovation. "Bridges come in families, with similarities in characteristics and systematics," Olthof continues. "Knowledge about those similarities can be compiled and shared anyway. You can also come up with a joint approach per 'family' in terms of maintenance, renovation or replacement. We already work together a lot, but it is imperative to take that to the next level and step over our own shadows. With Smarter Renovation and Replacement Together, IFD is one of the opportunities to build a new generation of bridges and viaducts, without having to set up a new organization or layer of government."

Standardize

"IFD for movable bridges, such as the Cruquius bridges, is about standardizing interfaces of components," explains Petra Muskens. "Consider, for example, notches at the bearing points of girders on supports and the dimensions and center-to-center distances of anchors at pivots and railings." Muskens was involved with the Cruquius bridges as Technical Manager and is now responsible for the entire bridge replacement and maintenance programming in her current position as Asset Manager for Artworks. "The same principle applies to the balance, the bridge basement, the location of the movement mechanism or a guide rail," she says. "By standardizing these interfaces, replacement becomes easier in the future because you don't have to demolish for customization.

It also increases opportunities for reuse. Moreover, the design phase is faster. This standardization is laid down in the NTA 8086 'IFD construction movable bridges' (Dutch Technical Agreement; ed.) from 2020. The Cruquius bridges is a pilot from which we learn a lot and whose knowledge has been used to further improve this NTA. As a public client, you have to take the lead with these kinds of developments and pick up and implement them together with market parties."

In addition to NTA 8086, there are also NTA 8085 for "IFD construction of fixed bridges and viaducts" and NTA 8089 for "IFD construction for IA&E installations of movable bridges.

Design

Client and contractor were each half responsible for the design. The province did not give the market parties a design, but functional requirements, with IFD as a hard contract requirement. The province (with support from engineering firm Witteveen+Bos) and Van Hattum en Blankevoort (with engineering firm IV Infra) jointly developed a final design through a construction team collaboration. This design was then developed into an execution design with Van Hattum's design team and is now being executed by contractor combination Van Hattum and Blankevoort - Hollandia Infra, which is about halfway through the V&R operation. Bas Coosemans, Project Manager of the construction combination: "The 1932 bridge has been completely demolished, including the foundation. After the traffic diversion, we will dismantle part of the second bridge, including the halyard, which will go to Hollandia in Krimpen for a complete renovation. In its place will be a temporary movable bicycle bridge. The towers and balance belts will also be completely renovated, and all hydraulics and mechanicals will be replaced one-by-one. When this renovation is over, the existing bridge will be able to last another 30 years."

Connections

The new bridge has a number of components that can also be applied to other drawbridges. These are mainly the connections of approach bridges and the halyard to supports and substructure, the pivot points of the movement mechanism and the technical spaces. "The tight location, the dikes with houses and the pumping station nearby narrowed our IFD scope somewhat," Muskens explains. "For example, the abutments were made with girders and a compression layer. In the future, however, we want to switch to, for example, box girders coupled with prestressing but without attachment, so that it becomes truly demountable."

Energy neutral bridge

The operation does go full steam ahead in terms of sustainability, circularity and energy neutrality. Coosemans: "The fact that you renovate an existing bridge is already very sustainable. Furthermore, all the materials and components used have a materials passport. In collaboration with the Concrete Innovation Laboratory and the Omgevingsdienst Haarlemmermeer, geopolymer concrete was used for parts of the bridge and an element of the new pedestrian tunnel, which is also continuously monitored. Performing the entire bridge in geopolymer concrete was not yet possible. Furthermore, the technical rooms are conditioned by a heat exchange system in the foundation piles, which was installed vibration-free - due to surrounding buildings. In combination with the field of solar panels, the bridge is completely energy-neutral in operation."

Future

For the province of North Holland, the Cruquius Bridges project is part of a process that never stops. Olthof: "Increasing sustainability, standardization, circular and low-maintenance construction are developments that you have to take the lead in as a client, think of cementless concrete and sustainable asphalt. Where five years ago you still had to have discussions about money for sustainability and circularity, this is now partly the standard. IFD is the future for us, because in the huge V&R task it can provide long-term savings. Not only on moving bridges like in Cruquius, but also on fixed viaducts and other structures. We won't have to be bored in the coming years."