Sustainable concrete plant: everything under one roof

In a time frame of just 45 weeks, Bosch Beton's new, 3.3-hectare production facility was completed. The new facility in Barneveld is the most sustainable concrete plant in the Netherlands and completely grafted onto a sustainable production process with all process steps under one and the same (imposing) roof. Thanks to optimal cooperation between all chain partners, including UBO Engineering for the concrete plant.

In a time frame of just 45 weeks, Bosch Concrete's new, 3.3-acre production facility was completed.

Bosch Beton's new state-of-the-art factory is located on a thirteen-hectare plot of land right next to the A1 motorway. "At our old location in Kootwijkerbroek, we could no longer grow any further," begins Brechtje van den Beuken-van den Bosch. "Reason enough to look forward to the possibility of new construction at a new location. Our ambition was to set up the entire production process as clean and sustainable as possible with a view to the (circular) future." Gerard van den Bosch adds: "The entire building was built BREEAM 'Outstanding'; in addition, almost all process machines are also new and developed in-house. From the old location in Kootwijkerbroek, we only took the formwork with us."

Recessed central station.

Energy neutral

The process installations were the starting point for the building design, Gerard continues. "These were thought out and drawn out in detail. Around this, the building was designed to stand on its 'own legs. During the construction phase, both construction processes of the building and the process installations had to be very closely coordinated. This is only possible with reliable partners, who fulfill their delivery agreements. In theory, the process installations could eventually be dismantled so that the hall could take on a second life." Brechtje: "It fits in with our sustainable philosophy that we also pursue as the second generation Van den Bosch, to be able to produce as much as possible energy-neutral. The energy consumption is compensated with over 18,000 solar panels on the roof, but also the rainwater that falls on the roof is used. This is collected in a 2,100 m³ basin, filtered and used as process water." In time, the market leader in retaining walls will be able to produce retaining walls even 100% circularly.

Heart of the factory

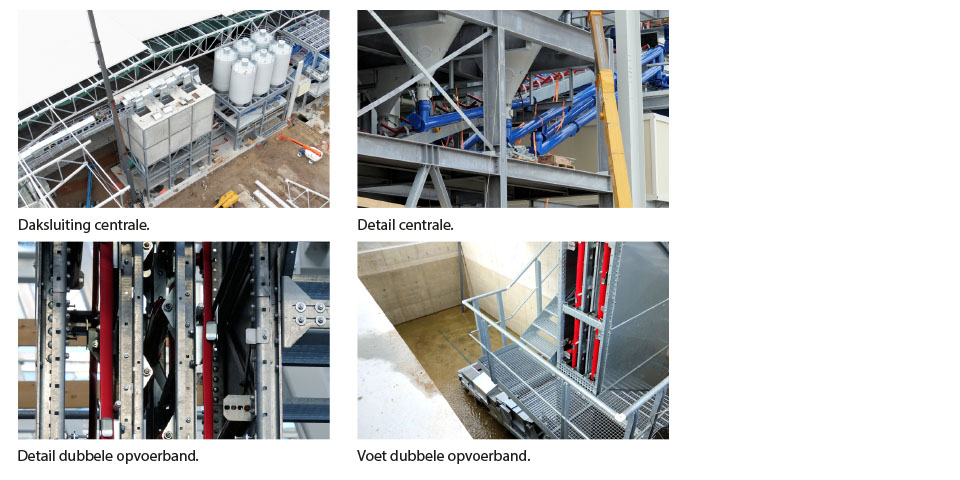

At the heart of the new concrete plant is the concrete mixing plant. "For the design and engineering of the new mixing plant, we engaged UBO Engineering," says Gerard. "We already had good experience with UBO at our previous location, as supplier of the Haarup mixer. The same blender was installed at the new location. It is the largest blender available on the market. In addition, UBO managed to surprise us with some innovative solutions in the process, such as the S-band. The conveyor is able to process raw materials vertically with a capacity of 300 tons/hour." Brechtje adds: "UBO Engineering took us in the preliminary process to other manufacturers with new installations to see the product innovations in action. That helped us tremendously in making the right choices."

"We like to work with reliable partners," Gerard summarizes. "In the end, convenience and delivery reliability are at least as important as price. Thanks in part to that reliability, we were able to meet our construction deadlines and save construction lead times. Recently, UBO Engineering disassembled the mixer at the old location and added it to the new plant. We are now in talks again for another expansion."