Unique new warranty for used channel boards

Manufacturers must dare to guarantee quality harvest

Upcycle Mall is an environmental park whose main building will be built completely circular. VBI from Huissen is supplying used channel plates for this with a unique new-build guarantee. Peter Musters of VBI says, "We already offer a return certificate to take back delivered hollow core slabs at the end of the life of a building. We also try to stimulate the market to de- and remountable construction. Now we are adding a third element to that, refurbished hollow core slabs with warranty."

"The municipality of Rotterdam has an ambitious sustainability policy." Speaking is Marc Verheijen, architect for the municipality of Rotterdam. "If you then build an environmental park, you do it circularly." That's easier said than done. Building circularly is a different construction process. You don't know what materials will be available when and what the quality and price will be. "Involved parties should therefore sit down together as early as possible," said Henk de Kruijff, project manager at the Roseboom Group and responsible for dismantling the VBI hollow-core slabs from a demolition project at Schiphol Airport. "If you know the demand from the beginning, you can estimate much better what to harvest when. Circular construction mainly requires cooperation and communication."

Aesthetics and reuse

Circular building is all about availability and reuse. The basis of the Upcycle Mall is a donor building with a visible, dominant steel structure that served as a laboratory at TNO in Delft. Verheijen made an initial sketch based on that building. "I called Jeroen Grosfeld of N3O Architects, the original designer, and together we drew up a plan for reuse. Meanwhile, the building lies disassembled in parts ready for reuse in Rotterdam. Almost everything was reusable except the floor, because it was poured in situ."

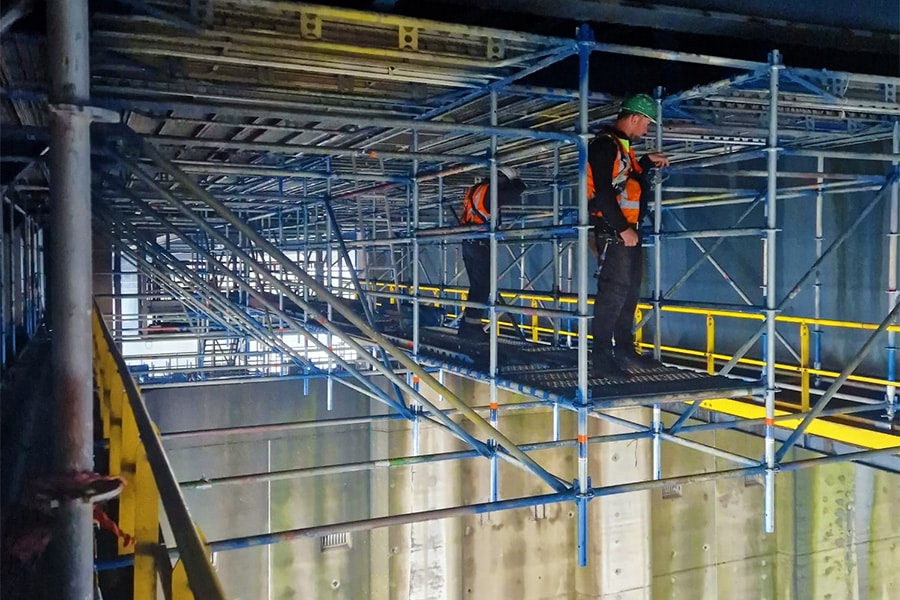

GKB contracted the foundation and ground floor of Upcycle Mall. Hans Bevelaar of GKB found a large number of used hollow core slabs in a demolition hall at Schiphol Airport. These were assessed and checked on site by VBI. The reinforcement was also carefully checked. There is an overdimensioned load capacity in the plates, making them safe to use. The harvested slabs were cut to size by Roseboom and fitted with EPS insulation. VBI has given the channel plates a new identity. With that, the quality is guaranteed by VBI. This is unique and important because it gives clients assurance that the hollow-core slab floor is safe and meets all requirements.

Blueprint

According to Peter Musters, Construction Projects Advisor, VBI is accelerating refurbishing and reuse. "Channel boards are too high quality to granulate and landfill. A refurbish trajectory starts with our return certificate for new remountable projects. Subject to conditions, we take back duct sheets at the end of a building's life. A process then begins that ensures these slabs go back into construction safely and as new. Data from the Upcycle Mall helps us optimize this process. Data on engineering, assembly, sizing, identification, inspection and transportation are reviewed. All the learnings lead to a blueprint for a refurbished process that starts with the identification of used slabs and ends with the redelivery of those slabs with warranty and a new identity."

Alternative

Marc Verheijen and the Municipality of Rotterdam are now learning a lot about demountable construction and reuse of materials. "It requires a lot of materials science and construction knowledge. Building requirements must be achieved with what is available or what is available on a 'second-hand market.' That requires flexibility. At the last minute, a product may not be there after all, and you can't wait any longer. Then you have to have an alternative." Originally, paving was planned in the Upcycle Mall. GKB came up with used channel slabs. An opportunity for the municipality to learn how to properly and safely reuse channel plates within existing regulations.

Neck sticking out

Tools like Madaster and Insert are helping to move circular construction forward, but the government in particular must be the driver by increasing circular procurement. "The task at hand is huge," said Musters. "To succeed, we need to share more knowledge and cooperate better. We hope that manufacturers, like VBI, are willing to take material back. We are slowly shifting construction from linear to circular, but it can and must be done even better and faster. It will work, especially if the government creates legal frameworks. By helping each other, we ultimately help ourselves."