utrecht RIVM/CBG | Intensive concrete job at Utrecht Science Park

The construction of the new housing of the National Institute for Public Health and the Environment (RIVM) and the Board for the Evaluation of Medicines (CBG) was another great opportunity for RED Betonbouw to demonstrate its ample knowledge and expertise in practice. Using the varied expertise as a basis, the VCA*certified concrete specialist using first-rate materials, equipment and manpower to complete the entire substructure of the eighteen-story building. The job was completed without any problems worth mentioning and is described by contractor Jaap Troost as intensive, comprehensive and a lot of fun to do.

Since its founding in 2010, RED Betonbouw has been steadily gaining ground when it comes to the realization of the most diverse concrete works for both residential and commercial construction. The assignment successfully completed at the Utrecht Science Park therefore perfectly matches the DNA of the Oud-Beijerland-based company. This is also the opinion of Marin Medic, work planner within RED Betonbouw. "Spread out over 2018 and 2019, we were commissioned by main contractor MEET RIVM CBG B.V. (MEET, ed.) to excavate the entire substructure of the building right down to the first floor within a total time frame of forty weeks with an enthusiastic execution team. Roughly speaking, this involved the basement floors, basement walls and floors of the first floor. A job that was tailor-made for us and in which we were able to apply our expertise to the full."

The 1.80 meter high floor formwork, traditionally made with bracing to double row of concrete blocks in the sand. Behind it, a welded reinforcement bar was placed to prevent sliding of the formwork.

Traditionally performed

Among other things, RED Betonbouw signed for the pouring of a massive floor pile with a height of 1.80 meters, an area of over 3,000 m2 and a volume of no less than 5,445 m3. On top of the floor, 600 millimeter-thick outer walls were installed. The concrete hulk was designed in such a way that the specified vibration requirements were fully met. "Instead of using a wall box, we put the entire floor in traditional formwork," said Troost. "And that had everything to do with the less favorable conditions on site, especially in terms of available space and subsoil. It is also worth mentioning that we poured the floor in one go using four concrete pumps to avoid cracking, due to the large amount of concrete."

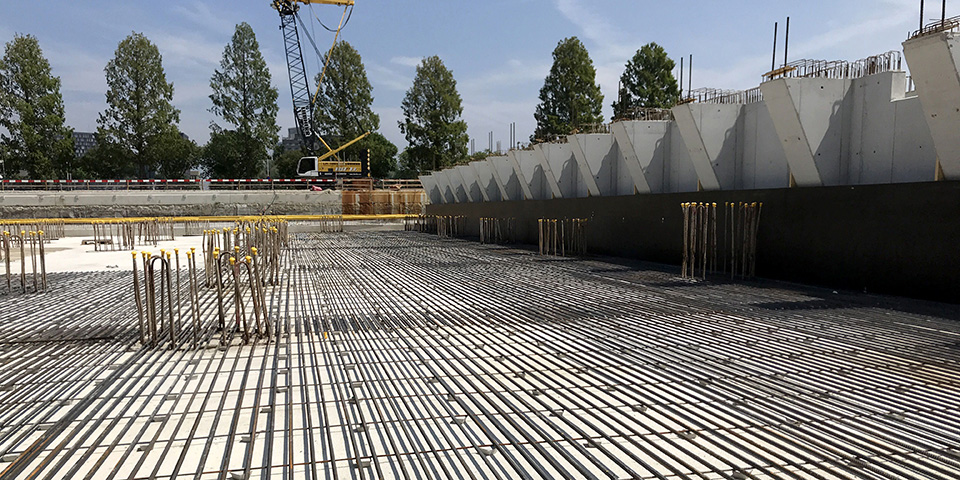

Reinforcement of the 1.80 meter high floor (poer). On the right, the buttresses and traditional formwork for the pier.

Double benefit

In order to be able to place the formwork faster, work more flexibly on site and drastically reduce the number of square meters of wide slab, RED Betonbouw opted to combine the U-Bahn boxes with floor formwork instead of wide slab floors. "Whereas the original intention was to construct the entire floor with wide slabs incorporating the U-Bahn boxes, it was ultimately decided to combine them with floor formwork. A decision that delivers double benefits. On the one hand, you reduce the number of square meters of wide slab, and on the other hand, it results in a tremendous weight saving," Medic said, then went on to touch on the other works performed by RED Betonbouw. "The buttresses we placed were realized using a combination of MAXIMO wall formwork and traditional formwork. This makes for a very impressive sight."

For more information on this project, visit