Slimmer, cheaper, more efficient construction with beams available from stock

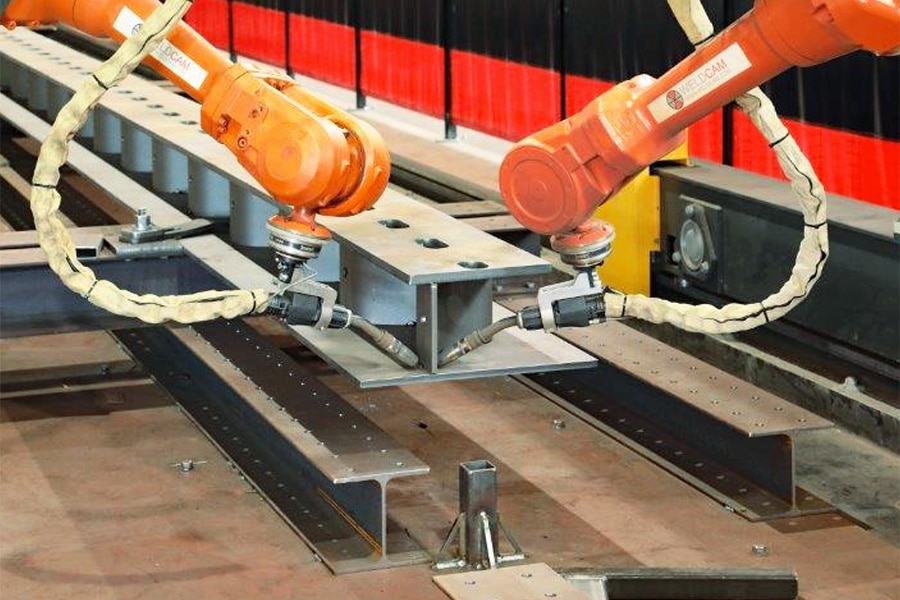

Building shells can be done faster, more efficiently, and more cheaply, thought Mouw Hoedliggers. With that in mind, the steel girder manufacturer from Ede developed the Sigma Beam. This versatile girder is suitable for circular and demountable construction and designed with a fire-retardant sheet pile profile. A newly developed rail system makes it possible to place connectors in any desired location, allowing beams in a number of standard sizes to be kept in stock. With a semi-automated welding process, an order can be delivered in just two to three weeks.

“The idea for the Sigma Beam arose from the fact that with traditional beams, you always have to wait for the floor plan before you can start production,” explains Sjoerd Willemsen, Head of Operations at Mouw Hoedliggers. “That's why we used our own engineering department to design a beam that we can pre-produce and that fits into virtually any floor plan.”

Anchor rail

The Sigma Beam derives its name from the characteristic wave shape in the girder. Willemsen: “That wave gives the girder its strength and makes it slimmer. We save about ten to fifteen percent in weight. Normally, you have two sides that are, for example, 8 millimeters thick, but with this girder, a single 12-millimeter waveform is sufficient. This profile is formed in the factory using a bending machine, which ensures consistent quality and high production speed. The bottom plate acts as a support and has recesses for plating and standard column holes.” For the Sigma Beam, Mouw Hoedliggers has developed an anchor rail that eliminates the need for floor plans and cutting drawings. “With this rail, stud positions can be placed anywhere. All we need to know from the floor manufacturer is how high the studs need to be. We then mount the rail on the girder and all that remains to be done on site is to screw the studs in to size.”

Specific requirements

The joist is suitable for hollow core slabs, wide slab floors, and steel plate concrete floors and is primarily intended for non-residential construction. “We can customize the beams in the factory based on project-specific requirements,” says Willemsen. “Not only do we cut the order to size, we can also add partitions for extra shear strength, install corner lines to accommodate different floor heights, provide suspension in an edge beam for facade constructions, and powder coat or paint the beams. This means we deliver a largely finished product ex-factory, which saves the contractor time in the construction process.”

Fire resistant

An additional advantage is the fire resistance that results from the design. Willemsen: “The wave shape and holes in the upper flange ensure that when a floor is poured, the remaining spaces are completely filled with concrete. As a result, the floor construction is fire-resistant for 30 to 60 minutes without any additional fire-resistant coating. This is yet another factor that saves time and money in the construction process. All in all, we believe that Sigma Beam is a smart beam that responds to the growing demand for prefab, circular, and efficient construction. And it's available from stock!”