Innovative blasting and coating specialist has virtually every certification in house

Drecht Coating Services, better known by its acronym DCS, was recently acquired by three investors from the manufacturing industry. This makes DCS part of a business platform that focuses on steel construction and processing. Within this, it retains its own identity, but it gives the blasting and coating specialist from Moerdijk many new impulses by taking advantage of all opportunities this platform offers. Enough reason to get acquainted with DCS through commercial and project manager Stephan Kluit.

Kluit: "After studying Chemistry Technology, I worked in the offshore industry for five years. There I got to know DCS, where I have been working for 21 years now. After various positions, it is now my job to set the company lines."

Specialty coating

DCS can call itself 'proven expert' in the field of blasting and coating steel. Its customers are in multiple sectors, but particularly in the offshore, infrastructure and petrochemical industries. "In blasting, sand, grit or salt is sprayed against the surface at high speed, removing old paint, rust and contaminants. After blasting, the new or cleaned steel is protected with a paint system, but sometimes with aluminum, zinc or another metal alloy for a desired high durability. This is done under insulation (petrochemicals) or in offshore structures, for example. By thermally applying this metal to the steel structure, it is optimally protected against extreme weather conditions and corrosion. With our techniques, we can give steel structures up to 50 years of protection."

EMVI points

The site of DCS in Moerdijk is unique. The site extends over three contiguous plots with a total area of 44,000 m2. "Not only are our blasting and conservation sheds located there, but we also have a large assembly hall. Clients can assemble steel objects here. In addition, the site offers a lot of storage space. All this ensures a very short transport line where we take care of our own internal transport. And because of our location on the water, with its own RoRo and transshipment quay, large constructions are transported in an environmentally friendly and efficient way. All this saves a lot of CO2 emissions, an aspect on which we gain EMVI points in tenders." The innovative DCS has also been using residual heat from nearby industry for years and has recently invested in new transport equipment so that it can now handle the transport of construction parts weighing up to 180 tons by itself. It is also exploring the possibility of installing solar panels so that it can be completely energy-neutral in the future.

Stringent requirements

DCS has experienced specialists and superb equipment. That combination ensures that a wide range of construction requirements can be met. "Order requirements are becoming increasingly stringent, but customers are also coming up with tougher specifications more often. For example, we are on Shell's shortlist thanks to our so-called Shell certification as an Approved aluminum applicator." In addition, DCS meets the requirements of the Department of Public Works standard RDT 1032 and has the necessary certifications, including NORSOK M-501 for offshore. It also has its own in-house NACE-3 coating inspector and is a certified applicator for fireproofing coating systems. "I would venture to say that we can meet virtually all specification requirements in the field of steel protection," laughs Kluit.

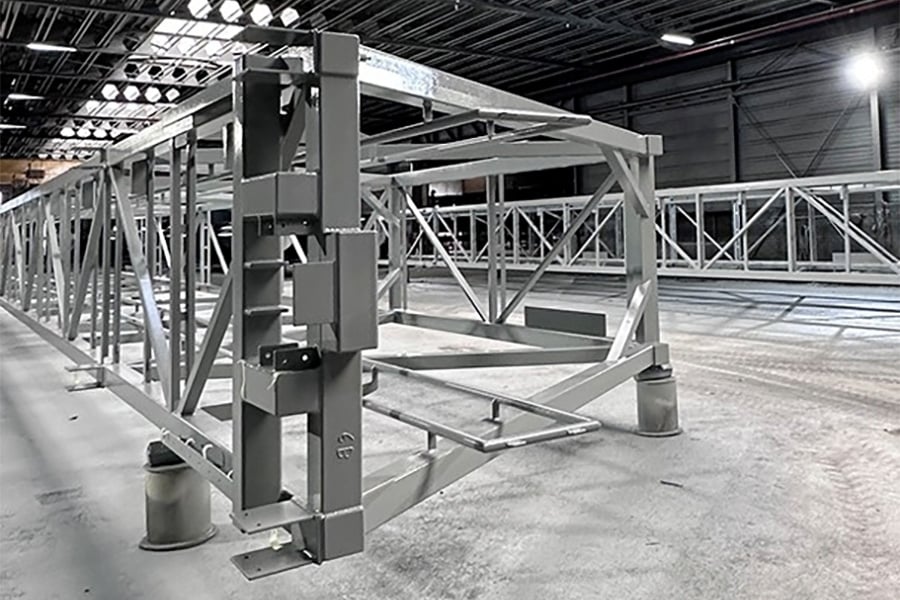

Projects with colossal objects

In recent years, DCS has renovated many guide and brake works in Zeeland for the Department of Public Works. "We are currently renovating the Kreekrak locks in the Scheldt-Rhine Canal. As a subcontractor of Heijmans, we are carrying out the conservation here in Moerdijk. You're talking about enormous lock doors of 13 by 26 meters. Each door weighs 170 tons and has a total surface area of no less than 2,000 m2. And we can simply treat these in our own conditioned warehouse!"