Innovative products for preventive protection and durable concrete repair

Concrete is a strong and durable building material that inspires a lot of architects, offers engineering firms opportunities to create tall buildings and large spans, and can be processed quickly and efficiently by contractors. Nevertheless, concrete damage can occur over time. However, this need not mean the end of the construction. After all, a durable repair is possible. To perform a quality and durable concrete repair, it must meet certain conditions. More about this is described in the standard NBN EN 1504.

Based on the diagnosis or preliminary examination, the nature and extent of the damage are identified, the repair method determined and the most appropriate repair mortar selected. Manufacturers provide a wide range of repair mortars, for aesthetic or structural repairs. Consider mortars for manual application or spray mortars applied mechanically. In addition to cementitious mortars, there are also mortars based on synthetic resins. The manufacturers, members of FEREB, can give you all the information about these products.

Innovative concrete repair products

Prevention is better than cure! Thus, a number of manufacturers developed additives, which can be added to new concrete or repair mortars. Here are some examples of these innovative developments:

In the case of reinforced concrete, the proper method must be followed to reduce and prevent corrosion. Concrete provides a natural shield that protects the steel reinforcement from corrosion. The highly alkaline environment created by the cement matrix around the steel reinforcement forms a passive layer around the reinforcement that prevents further corrosion. However, this protective layer is only maintained as long as the high alkaline environment of the concrete matrix persists. Carbonation, exposure to carbon dioxide dissolved in water, reduces the pH of the cement matrix. In addition, chloride ions disrupt the passive layer, causing corrosion.

Although the corrosion process cannot be avoided, one can slow down the process. There are several types of corrosion inhibitors on the market. They consist of chemical compounds that prevent corrosion reactions on the reinforcing steel. All inhibitors must get close to the steel reinforcement in the concrete to protect it. Therefore, corrosion inhibitors can be added to concrete admixtures, mixed directly into the concrete or applied to the surface of the cured concrete. The first type of corrosion inhibitors can only be applied to new structures; a second type is specifically designed for the renewal of existing structures.

Corrosion inhibitor with dual function

For example, Sika developed a new corrosion inhibitor that can be applied to both new and existing structures, even with post-coating cracks. This dual-function, silane-based corrosion inhibitor is applied to the surface. The inhibitor is suitable as part of a corrosion prevention, protection or inhibition strategy. It is a revolutionary blend of high-quality silanes with selective corrosion inhibitors that are dormant in the concrete until activated by moisture that penetrates the surface due to cracking or aging of the concrete. In addition, this product has a very low viscosity that improves penetration into the concrete over a wide temperature range. This makes application of the product and application much easier and safer than many traditional inhibitors.

The dual action thus consists, on the one hand, of the water-repellent effect of the high-performance mix of silanes, which prevents moisture and chlorides from penetrating the concrete, and, on the other hand, of a dormant inhibitor mixed with silanes. The presence of dormant inhibitors is crucial for long-term protection of reinforced concrete structures against corrosion.

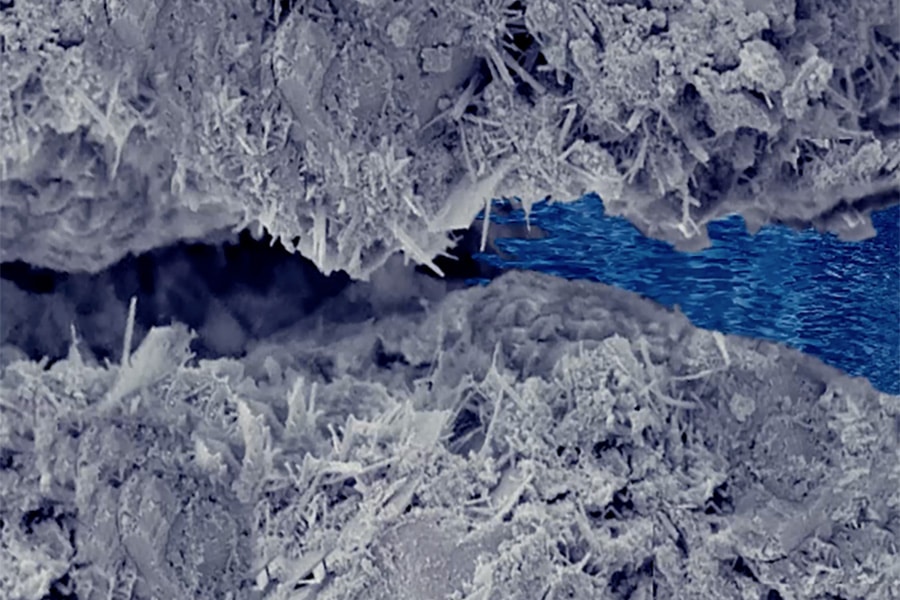

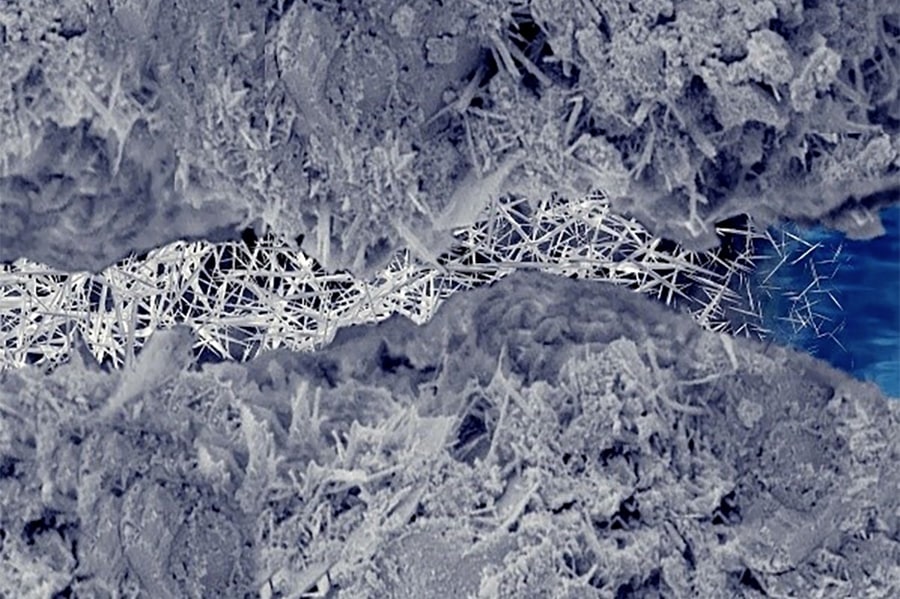

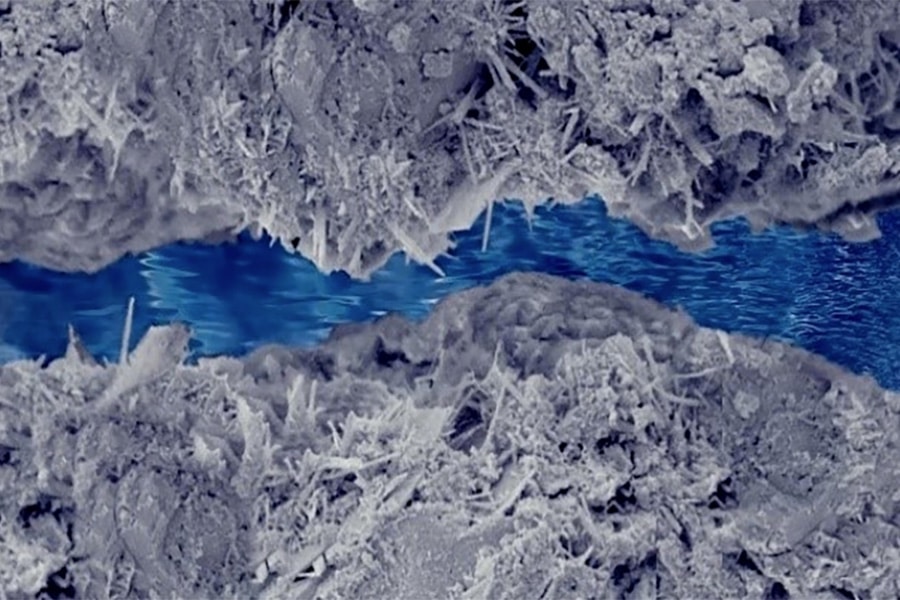

Self-healing concrete

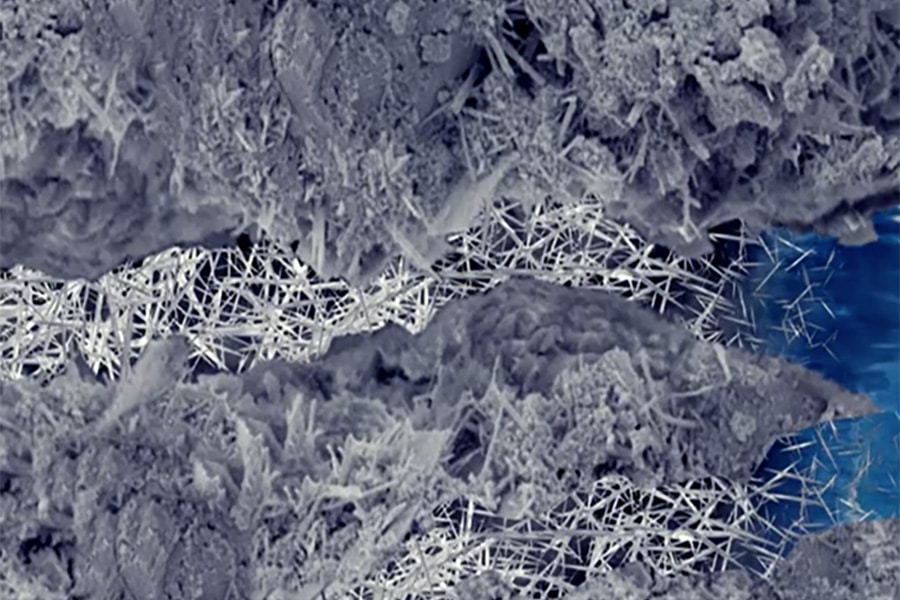

Thus, PENETRON® developed a self-healing system consisting of integral, crystallizing waterproofing and protection materials designed to protect concrete in depth. The product consists of a mixture of mineral chemicals. When the product is applied to concrete, the active chemicals catalyze a reaction with the water and byproducts of cement hydration to form new, insoluble crystals. These crystals chemically and physically bond to the concrete structure, filling the pores, capillaries and micro-cracks in the concrete and preventing water penetration. This reaction penetrates deeper and deeper into the concrete, even against the direction of water pressure. However, these reaction products still allow vapor to pass through, allowing the concrete to "breathe. The technology seals cracks up to 0.5 mm.

As long as no water enters the concrete, the active agents remain inert. As soon as moisture enters again through new cracks up to 0.5 mm, this will catalyze another reaction and these will be sealed with new crystals: the concrete is now self-healing!

Larger cracks, concrete joints and formwork holes can be repaired with customized repair mortars that are self-healing, thus also protecting the concrete all around. The system also works along the negative side and on damp concrete. The moisture in the concrete is even good and will help the active ingredients "penetrate" the concrete. After the active ingredients penetrate, they catalyze a slow reaction that forms new insoluble crystals. In the process, the water present is used up and the concrete dries out.

Fereb vzw cannot be held responsible for the content of this article.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met FEREB asbl.

Contact opnemen

Contact opnemen