Cement-free Belgian building stone marks carbon-negative revolution in construction

Masterbloc - Gubbels in Maasmechelen and Prefer in Flémalle join forces to produce Carbstone: the world's first 100 percent circular and carbon-negative building stone. This Belgian innovation marks a true carbon-negative revolution in the construction industry.

The construction industry faces an immense challenge: to reduce its carbon footprint without sacrificing quality and performance. Whereas concrete is traditionally one of the largest sources of CO2 emissions - mainly due to the use of cement, which accounts for about 7 percent of global emissions - Carbstone is succeeding in radically reversing this trend. Thanks to an innovative production method, CO2 is no longer emitted, but instead is permanently fixed in the stone itself.

How Carbstone came to be

Carbstone was born from decades of experience in building stone production, combined with pioneering research from Vito and innovative carbonation technology from partner Orbix. The company later joined forces with Prefer and today its products are available through multiple distribution portfolios, backed by numerous certifications attesting to its industry-leading quality.

Cement-free

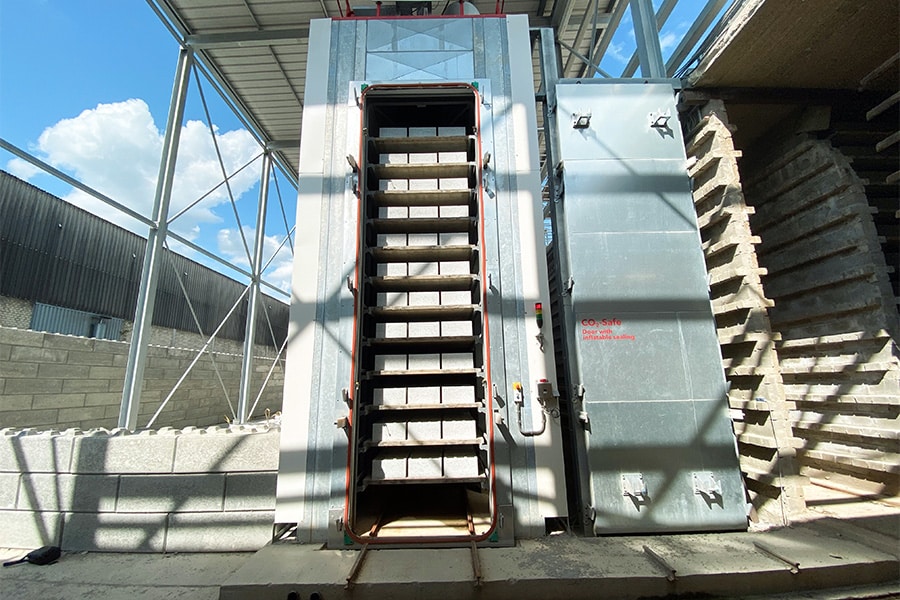

The core of the innovation lies in the binder. Where conventional concrete uses cement, Carbstone uses carbonated limestone and residues from the metal industry, such as steel and blast furnace slag. During the production process, CO2 is actively added. This CO2 reacts chemically with the residues and is permanently fixed in the material - a process known as controlled carbonation. This not only eliminates the need for cement, but creates a brick that absorbs more net CO2 than it emits. The result is a cement-free, 100 percent circular building stone that is stronger than traditional concrete and also contributes to carbon-negative construction. Even during its period of use, Carbstone continues to absorb CO2, making the brick literally ‘greener’ over time. At the end of its life cycle, the product can be easily ground into sand and gravel - fully reusable, with no loss of quality.

Circular production

Carbstone is the epitome of how circularity and performance can go hand in hand. The bricks are produced from 10 percent secondary raw materials, with no natural aggregates such as sand or gravel. This not only reduces CO2 emissions, but also eases pressure on natural resources. What also sets Carbstone apart is its far-reaching environmental accountability. Whereas most environmental declarations (EPDs) only consider the production phase, Carbstone's Sustainability Performance Declaration (SPD) covers the entire life cycle: from raw material extraction and transport to use, demolition and reuse. Each phase is optimized for minimal impact and maximum transparency.

This full life-cycle approach delivers something rare in the construction industry: total environmental transparency. Each stage is optimized, measured and accounted for - proof that sustainability is not just a label, but a process.

Robust production capacity

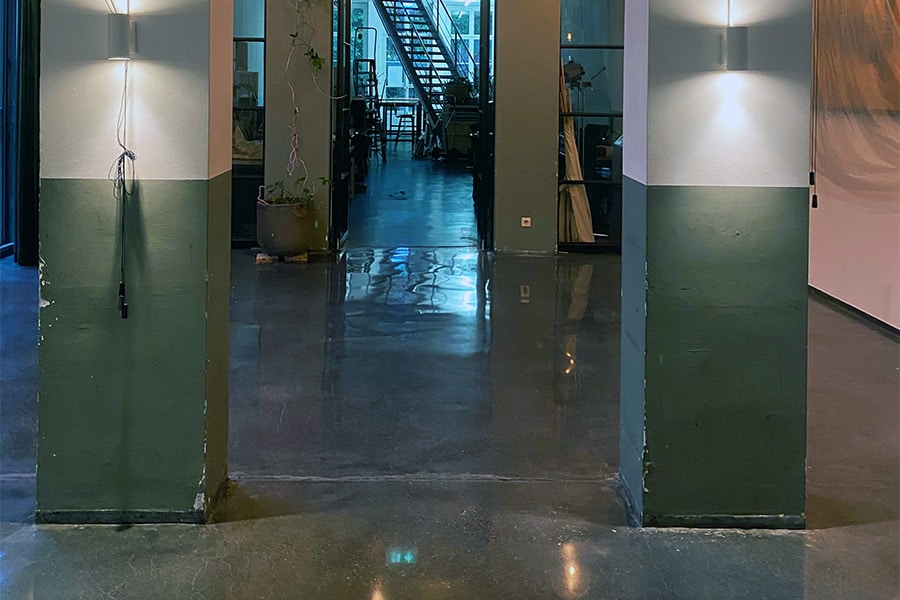

With production sites in Maasmechelen (Masterbloc - Gubbels) and Flémalle (Prefer), Carbstone has a robust production capacity capable of serving the entire Belgian territory and surrounding markets.

Carbstone proves that performance and our planet no longer have to be opposites. The brick combines structural strength, fire and frost resistance with a net negative CO2 balance. This makes it not just another building product, but concrete proof that the construction industry is capable of reinventing itself. At a time when circularity is no longer a choice but a necessity, Carbstone shows that sustainability need not be a compromise - but an opportunity to build better, stronger and smarter. Belgium can be justifiably proud of this world first: a building stone that literally lays the foundation for a low-carbon future.