Final sprint to 100% CO2 neutrality is underway

Concrete façade panels and sustainable construction

Manufacturer of prefabricated facades in architectural concrete and natural stone for residential, office and utility complexes Loveld nv has long been committed to sustainability. Previous initiatives in this area include solar panels, the collection of rainwater, water purification and the electrification of the vehicle fleet. Meanwhile, the company is fully committed to excluding cement from the production process of concrete. First via low-CO2 concrete and later, by 2050, on completely CO2-free concrete.

Thorough research

Project sales & development manager Vincent Termote: "In cooperation with ResourceFull, a technology start-up, we have been investigating for some time the possibilities of making low-CO2 concrete by adding blast furnace slag. First with gray concrete and in a subsequent phase with (colored) architectural concrete. We were encouraged by the stricter requirements in our main markets the Netherlands and the United Kingdom and by the BREEAM guidelines for building materials and techniques. We have therefore already drawn up a roadmap up to 2026, in which we define which interventions will enable us to climb even further up the ladder of low-CO2 concrete."

Environmentally friendly cement substitutes

Systematically switching to blast furnace slag is not a foregone conclusion. The low-carbon and later CO2-free concrete must be at least as strong as the traditional concrete based on 100% cement. Cement production is admittedly a particularly polluting activity, which is why Loveld, and by extension the entire industry, started looking for environmentally friendly cement substitutes.

Blast furnace slag, a waste product from the steel industry, meets these requirements perfectly. Loveld has succeeded in putting together an ideal mixture of cement and metal slag that guarantees particularly high-quality concrete that meets all (aesthetic) requirements and regulations.

Ground granulated slag (GGBS).

It should not be forgotten that around four billion tons of cement are processed worldwide each year, accounting for over 8% of total CO2 emissions. Much of this is caused by cement production itself and is related to the extreme heating of the cement base to temperatures of 2,000°C. Civil and Marine Ltd, Sir Michael Uren's British company, found that ground granulated slag (GGBS), a waste product of coal-fired power plants, was useful as a sustainable substitute for cement in concrete production. She also found that through the addition of GGBS, the strength of concrete is maintained while only one-fifteenth of the emissions are emitted.

Important pilot project in London

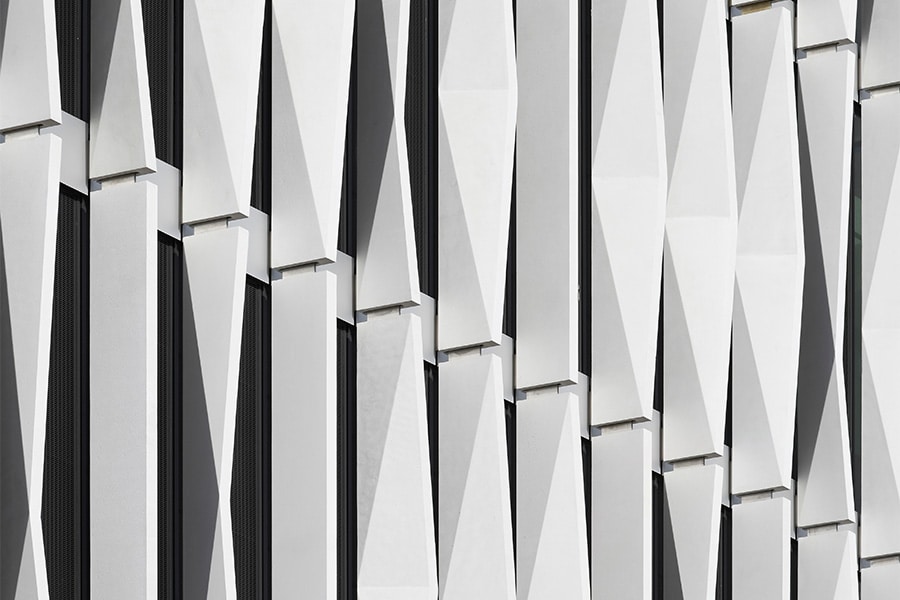

Through its British subsidiary Loveld UK Ltd, East Flanders-based Loveld was involved in the construction of the Sir Michael Uren Hub, which opened its doors in 2020. The Hub is a department of Imperial College London, conducting biomedical research into musculoskeletal disorders, hip replacement and neurological diseases such as dementia. Since the low-carbon project was funded by a donation from Sir Michael Uren himself, it took on added symbolic value for Loveld in terms of the application of low-carbon concrete. Loveld was responsible for the production of the precast concrete façade fins. These concrete façade elements were produced with 40% less CO2. The 13-story building houses an auditorium with 160 seats, social areas, clean rooms and futuristic outpatient clinics. The building was constructed in a concrete frame structure and given a glass facade with three-dimensional fins in architectural concrete, resulting in excellent sun protection as well as striking aesthetics. Termote: "We formulated a concrete mixture especially for these fins, in which the blast furnace slag was added manually. The single-shell vertical fins were made with a mixture of 50% cement and 50% GGBS. In total, we produced 1,300 fins in seven basic shapes. This allowed a beautiful facade to be realized with limited production impact."

Loveld, together with its research partners, is fully committed to exploring cement substitutes other than GGBS to achieve 100% CO2-free concrete by 2050.