Giving reinforced concrete a longer life

Cathodic Protection (RD)

Corrosion of rebar is disastrous for the long-term stability of concrete structures. It is a natural electrochemical process caused by electrical stress differences between steel and concrete, resulting in corrosion.

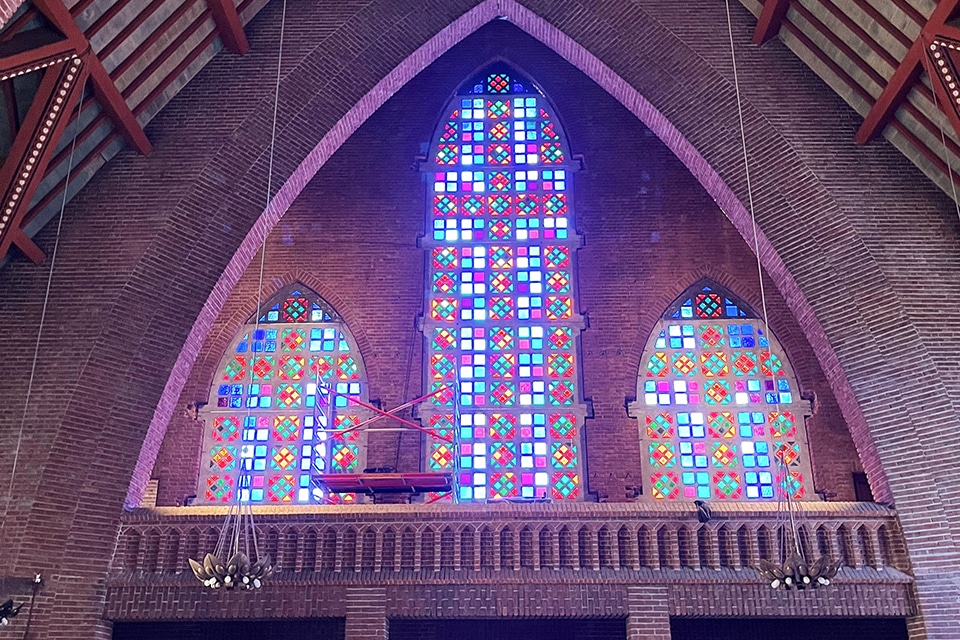

The Belgian company Renotec nv is particularly active in repairing reinforced concrete structures with the specialty of Cathodic Protection (RD). It uses these techniques to protect the reinforcing steel from corrosion, thus extending the life of bridges, tunnels, (heritage) buildings and other concrete structures in a sustainable way.

How does cathodic protection work for rebar?

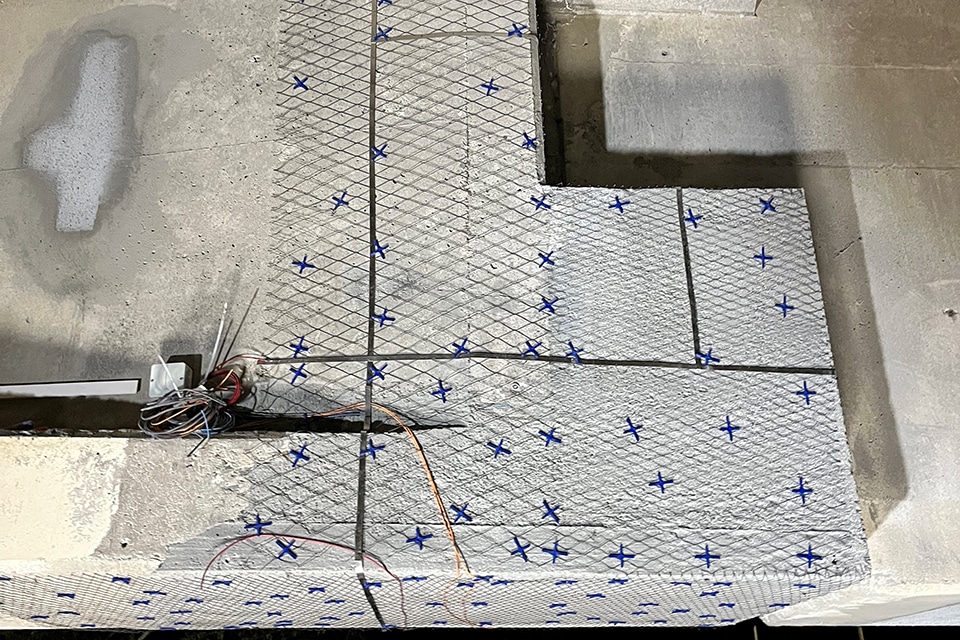

Frederick Crevits, principal project manager at Renotec nv: "Due to voltage differences in the concrete-steel mix, the reinforcing steel acts as an anode. This releases iron and hydroxide ions to the concrete (cathode), causing rust on the steel. The corrosion process can proceed even faster due to the presence of chlorides in the concrete. The solution to this is as simple as it is ingenious: by permanently administering a light direct current to the concrete, the roles are reversed and the reinforcing steel becomes cathodic instead of anodic. In practice, this is done by adding a very noble metal to which voltage is applied. This metal will then assume the role of anode. Usually this is mixed metal oxide-coated titanium in all kinds of forms (strips, gauze, coring cylinders, etc.), which is embedded/injected with a cementitious material. There are even coatings on which current can be applied and thus serve as an anode."

Renotec nv has its own specialized and qualified staff, including project engineers responsible for preparation and site follow-up. But also its own workers who carry out the project from start to finish. This allows Renotec nv to handle complex concrete renovations with cathodic protection entirely with its own personnel and under its own management.

Two systems

Jana Goris, project leader at Renotec nv: "There are basically two types of cathodic protection. There is galvanic cathodic protection (GCP), which originated in the maritime world (ships, sheet pile walls, etc.). Here one works with galvanic elements (usually made of zinc) that are less noble than steel. As a result, the elements will act as an anode and sacrifice themselves to protect the steel. The other technique is cathodic protection with impressed current (ICCP), which my colleague Frederick has already talked about. Here one works with an external current source that will provide the protective current. This system has many advantages over GCP. For example, the system can be tuned to obtain optimal (cathodic) protection of the rebar. Because one is working with (MMO) titanium and an external power source, up to 100 years of protection can be guaranteed with minimal maintenance."

By applying cathodic protection, the service life of a reinforced concrete structure can be extended in a very sustainable way. Thus, concrete repair can be reduced to the minimum, as the RD provides further protection.

Further prospects

The future of concrete renovation with cathodic protection looks promising. Renotec nv is committed to continuing to provide innovative solutions that not only extend the life of structures, but also contribute to a more sustainable and environmentally friendly world.

Renotec nv specializes in concrete renovation, asbestos remediation, restoration and repurposing, pipe renovation, energetic renovation and the renovation of industrial sites. 35 years of experience and more than 900 employees guarantee innovative solutions in numerous niche markets.