Organic foaming agent is on the rise

For more than twenty years, Bouwservice Ravenstein has been active in the cement import business. On 'expedition' in Italy, owner Herwie Cornelissen came across a unique foaming agent to produce foamed concrete. Unlike conventional foaming agents, it is a 100% biological 'shampoo'. This offers numerous advantages and wider applicability of foamed concrete, according to Cornelissen. "Given its value for money, it is only a matter of time that the Netherlands will switch completely to this sustainable foaming agent."

Bouwservice Ravenstein is a supplier of an aggregate (powder) that makes the foam concrete water resistant.

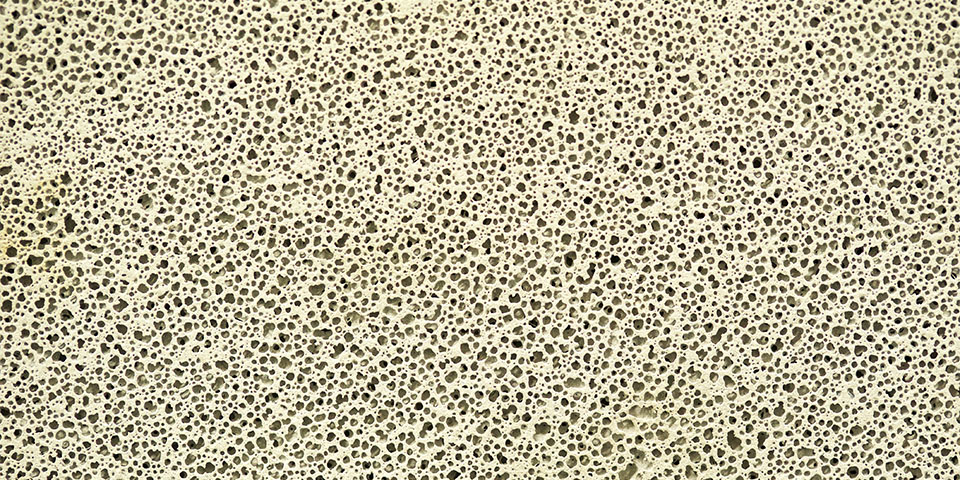

In the Netherlands, a handful of companies produce quite a few cubic meters of foam concrete every year, Cornelissen notes. "Foam concrete is basically a mixture of cement and water to which a foaming agent is added. Normally this foaming agent is an oily product or a protein-based product (animal waste, bull's blood). The product we market, however, is 100% organic. It is the only organic foaming agent in the world." Bouwservice Ravenstein sees numerous new application possibilities with this unique product, whether or not in combination with other additives.

Basalt fiber in foam concrete

To reduce plastic shrinkage, foam concrete has to date been reinforced with polypropylene fibers, or plastics, Cornelissen explains. "We commissioned a test with a reinforcement of basalt fibers, combined with our biological foaming agent. The results were astounding. First, a basalt fiber (molten rock) is one and a half times stronger in tensile strength than steel. On the other hand, this combination ensures that the foam concrete with biological foaming agent and basalt fiber can be recycled for 100% without leaving any microplastics behind, as is the case with polypropylene fiber. The result is also a much better carbon footprint. We believe there is a great future for this combination."

In the Netherlands, a handful of companies produce quite a few cubic meters of foam concrete every year.

Waterproof

And as if that were not enough, Bouwservice Ravenstein has another first. Cornelissen: "We are the supplier of an aggregate (powder) that makes the foam concrete water-resistant. This makes the possibilities for applying foam concrete even greater. Think of an application such as a balance foundation, as an alternative to piles or under bicycle paths and roads on dikes. Certainly in the Westland it offers plenty of opportunities. By excavating peat with a specific gravity of 1,200 kg/m³ and replacing it with foam concrete with a specific gravity of only 500 kg/m³, you can reduce and load a comparable amount with, for example, a structure, to its original weight. A win-win. Until recently, however, no one could guarantee water resistance. So now, with this unique aggregate, they can."

For (post-)insulation, too, Cornelissen says biological foam concrete in the form of mineral insulation is a better and more environmentally friendly alternative to the usual pellets that again contain micro-plastics. "Foam concrete is lighter, has good insulating properties and is more recyclable. In combination with blast furnace cement, it is a runaway race on many fronts."